Interest aroused?

You would also like to implement an aftersales project?

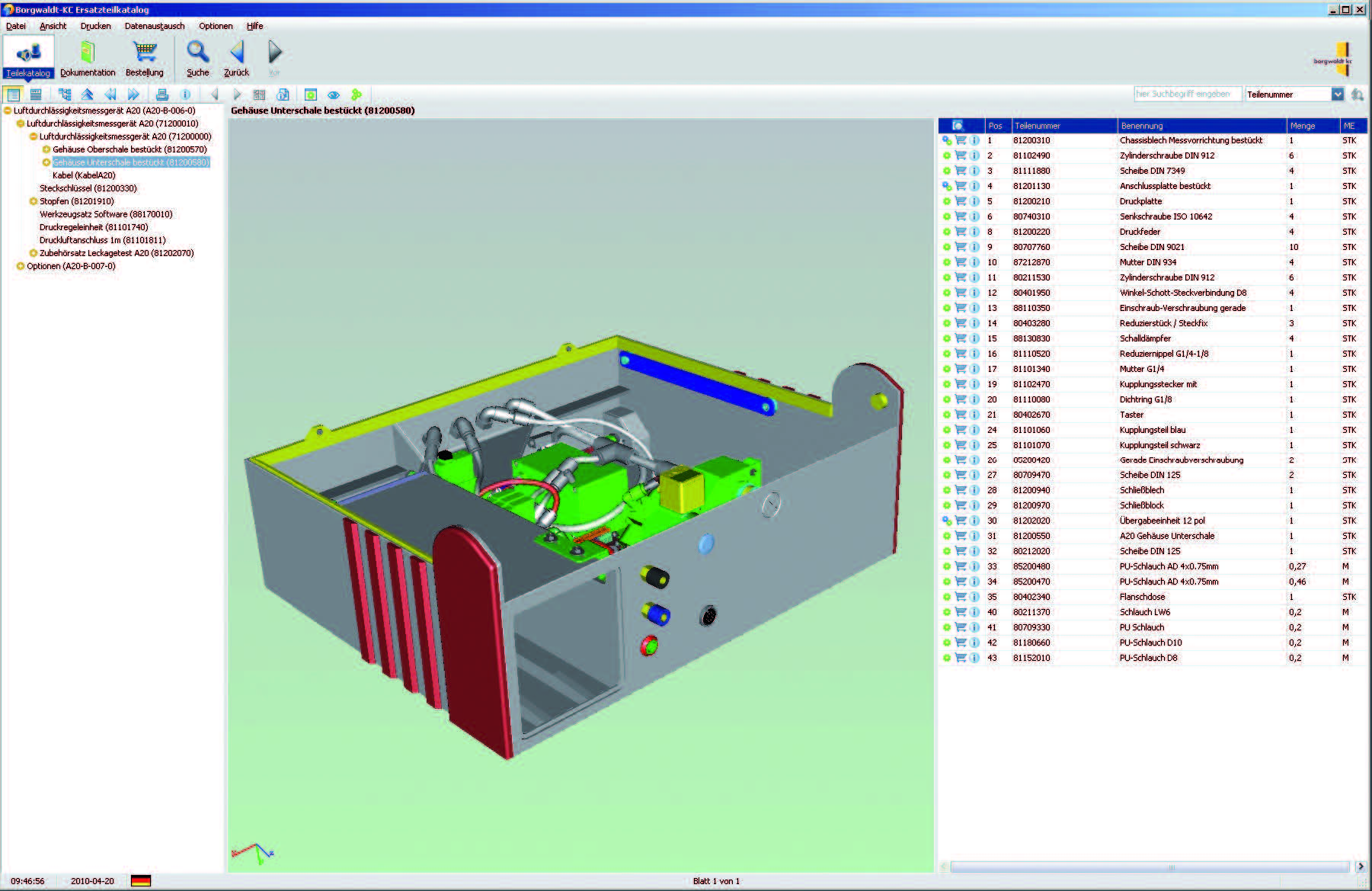

The Borgwaldt Group - first-point-of-contact when it comes to tobacco processing and blending - generates electronic spare parts catalogs with integrated 3D illustrations directly from NX. For the automated production of the parts catalogs from the CAD system Borgwaldt implemented Docware‘s spare parts catalog software PARTS-PUBLISHER with integrated JT Viewer.

Borgwaldt KC GmbH, a subsidiary of the Borgwaldt group, is a globally leading vendor of all quality control devices and machines used in the tobacco industry and its subsuppliers.

Based in Hamburg the company is specialised in manufacturing smoking machines, smoke analysis devices and other highly specialised laboratory apparatus. Borgwaldt KC offers the appropriate products for all areas: from research and development, incoming goods inspection and smoke analysis to production control. In order to optimise the service for technologically excellent solutions the company implemented a spare parts catalog system basing on CD that guarantees an easy and fast access to required spare parts information to customers and service staff.

Until beginning of 2009 Borgwaldt supplied manually issued printed spare parts lists to provide customers and service staff with spare part information.

With the implementation of the spare parts catalog system PARTS-PUBLISHER by Docware Borgwaldt optimised the provision, identification and availability of service and spare parts information. Customers and staff are equipped with a catalog CD with integrated search and ordering function tailored to the particular machine or devise.

Since a couple of years Borgwaldt designs three-dimensionally with NX of Siemens PLM. The CAD system is linked with Teamcenter, the PLM system of Siemens. It was obvious for Sören Sahling, head of the project „electronic spare parts catalog“ at Borgwaldt, that the 3D illustrations created with NX should be used for the spare parts catalogs.

JT models created with NX flow directly into the catalog creation with PARTS-PUBLISHER. For the data export from NX a special software was programmed. During export from NX a monolithic JT is created for every assembly. The JT files exported are filed in a file system and imported from there into PARTS-PUBLISHER. The JT files are compressed during export (Libra compression).

Additionally to the processed JT models from NX parts lists and master data from the ERP system - Borgwaldt works with Bäurer B2 - are imported into the Workbench of PARTSPUBLISHER. Here the 3D models and parts lists are automatically linked and catalogs are created with only a few mouse clicks. The production of a catalog takes about 90 minutes.

The Docware JT Viewer is supplied along with every catalog CD created with PARTS-PUBLISHER tree of charge for installation at the catalog user. The catalogs run on every PC or notebook with operating system Windows. 3D models and parts list data are linked in the spare parts catalog. When selecting a part in the parts list, it is automatically highlighted in the 3D model and vice versa.

By a single mouse click related information becomes visible at a glance. The extensive display functions of the JT Viewer allow for a number of interactions. Customers and service staff of Borgwaldt benefit from the 3D technology of the spare parts catalogs. 3D models clearly illustrate the structure, the position and the exact appearance of the machines, individual assemblies and parts. The models and their components can be pivoted, rotated and viewed from different angles. The zoom function allows you to zoom in and out on the models or assemblies. Selected parts can be displayed in a detail window additionally to the main view.

Also the view of the parts in the detail window can be modified interactively. For a better visualization of components parts can be faded in and out. The transparent mode also serves for making hidden parts visible.

The possibility to use JT data from NX directly for the production of spare parts catalogs offers a new potential regarding the efficiency of the catalog production and the quality of the catalogs created. 3D CAD data that had to be converted into perspective illustrations elaborately in the conventional mode can now be directly used for spare parts catalogs with PARTS-PUBLISHER and JT technology. With the integrated 3D illustrations the quality, clearness and information content of the spare parts catalogs improved.

“We wanted to avoid any effort to convert the existing JT data into 2D. That is why we looked for a spare parts catalog software that offers a perfect integration of JT.”

Sören Sahling, Head of project, Borgwaldt Körber Solutions

Borgwaldt Koerber Solutions

„PARTS-PUBLISHER of Docware, the first parts catalogue application with integrated JT Viewer on the market, met our claims all along the line.“

Mechanical and plant engineering

You would also like to implement an aftersales project?