The idea behind after-sales & service has changed completely in recent years and will do so even more in the future - at least on the part of suppliers. Customers have always been interested in comprehensive service, while product providers have often seen the provision of spare parts and services as more of a chore. In the digital economy, service "eats" the product; new business models virtualize the product and replace it with a service - which depends quite significantly on service.

The bad news is that manufacturers who cling to the traditional after-sales model risk getting into serious trouble sooner rather than later; this is particularly true for suppliers of technically sophisticated products in the B2B market. However, there are also two pieces of good news. First, establishing a service-based business model offers significant advantages. And secondly, mature software systems make the transition possible from any individual current state.

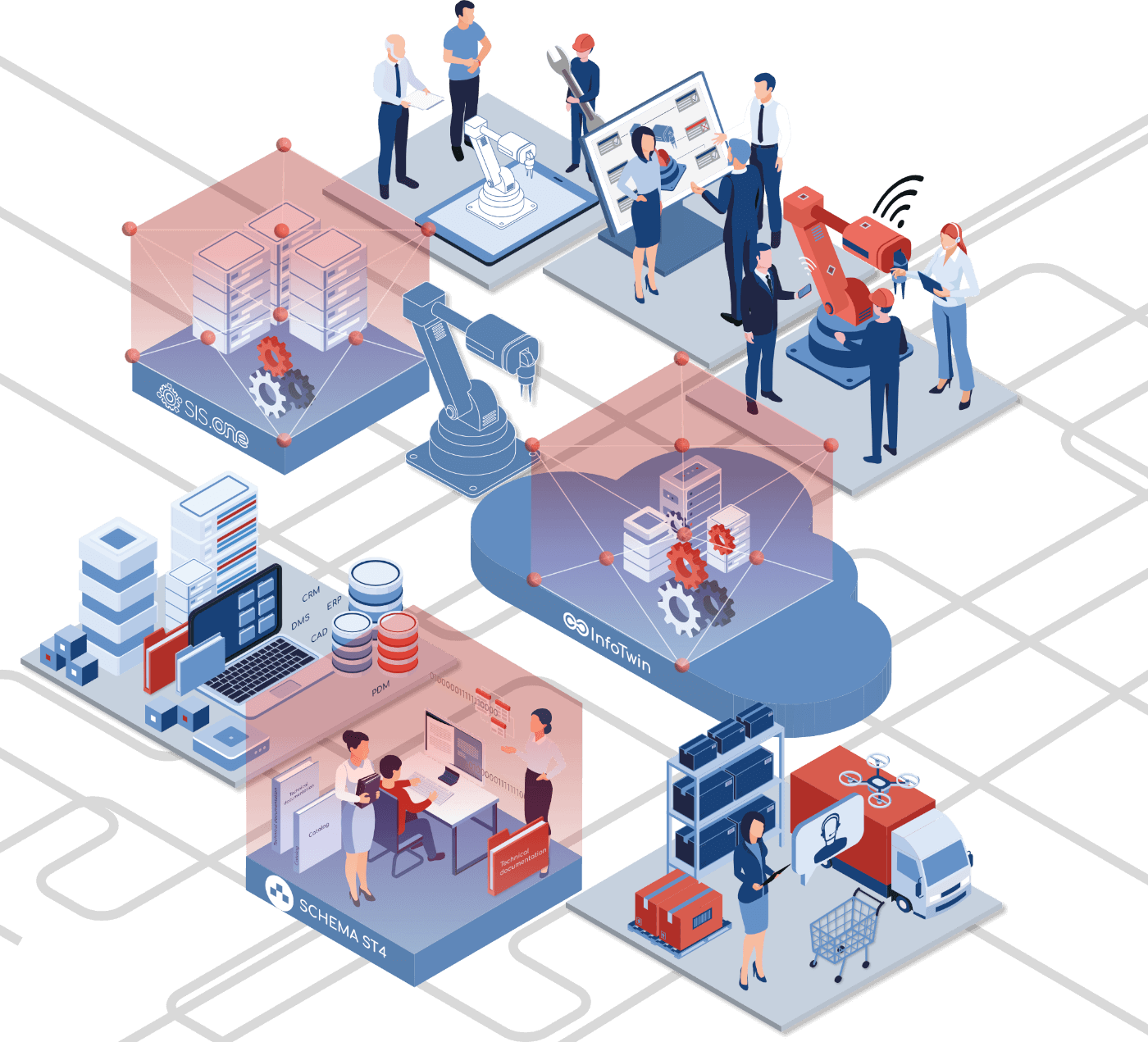

Digitalization is turning our world upside down in almost all areas. Not only products are becoming smart, but also their creation. Digital data is created in design and manufacturing, but also during use, and is available to all process participants throughout the entire product life cycle. A digital twin is created.

The connection of all information belonging to the product enables new business models, which in turn require new forms of product support. The Digital Information Twin is the basis for maximizing product availability and efficient service. Quanos provides the software tools that help create the Digital Information Twin.

Access via remote

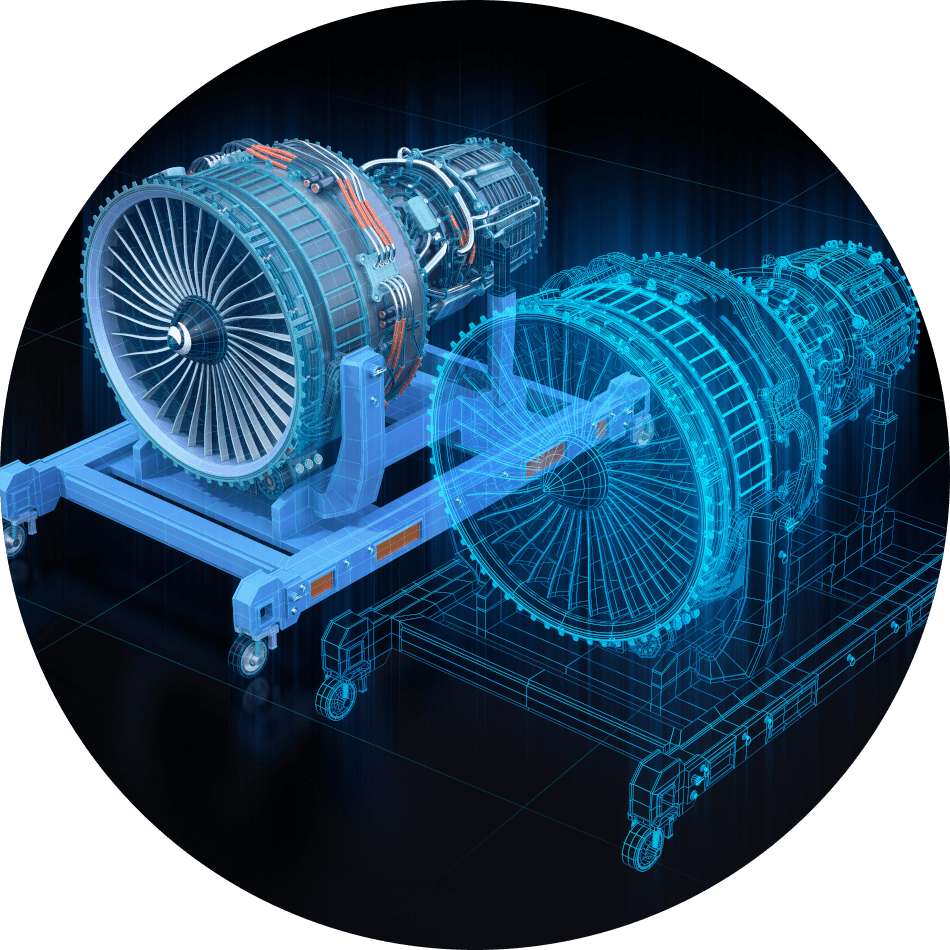

With the cloud-based technology myPlant*, customers of the gas engine manufacturer INNIO, can manage their plants securely and in real time from anywhere. By remotely accessing their machine's Digital Information Twin, customers control the operational performance and profitability of their gas engines and benefit from unprecedented insight into the performance of their industrial assets. INNIO's myPlant* solution can improve plant availability and efficiency and reduce total lifecycle costs.

Learn more about our Reference Story here:

Demographic change, an aging society and, to an even greater extent, the retirement of baby boomers from the workforce pose major challenges for companies: the war of talent and the preservation of specialized know-how that disappears when individual knowledge carriers (the so-called space cowboys) leave the company.

The adaptation to new job profiles or the more efficient use of employees through intelligent software solutions that also preserve valuable knowledge are possible answers to the shortage of skilled workers.

A revolution is underway in the field of maintenance and service: With the feedback that IoT technologies enable from the machine back to the upstream processes, not only does valuable information get back there, but completely new service and business models become possible. On the way to the new service world, there are many intermediate destinations and advantages - if you know where you want to go

Depending on the degree of digitization, networking and intelligence of the available data and information, everything seems possible: from the operational maintenance of individual machines to intelligent predictive maintenance to reality-based maintenance of an entire machine fleet. How these next steps on the way to smart service and intelligent maintenance look like, we present in another whitepaper.

Read Whitepaper now

Curious now? Read the whitepaper on smart information enabling smart services now.

What's more, have you already seen it? We have something else on offer

Interview with Martin Steuer:

>> How the DIT enables new business opportunities