- Field Service Management (FSM) describes the process of the operational planning of personnel and other resources in the field.

- In FSM, back-office staff (planners) and field service engineers work together, coordinated by field service managers.

- Digital FSM solutions form the basis of optimal operational planning, relieving the pressure on everyone involved.

- Some of the greatest FSM challenges include the shortage of skilled workers, increasing volumes of data in the service business, and documenting information.

- Efficient field service management increases customer satisfaction and improves sales potential.

3 Facts: Why is Field Service Management Essential for Manufacturers?

- Only one third of plant and machinery construction businesses have an aftersales service strategy - even though the aftersales business for a company’s own products has a significant impact on turnover these days.

- To maximize sales potential, manufacturers need cutting-edge workflows in all areas of their business - particularly when it comes to field service management in aftersales.

- The aim is to fix malfunctions quickly and effectively, and thus keep workloads down to a minimum. When it works, FSM helps manufacturers, engineers, and customers to save time and money.

Challenges in Field Service Management

Service engineers need to complete their field service operations reliably, confidently, and with high quality results, to ensure the company retains its competitive edge. However, the work undertaken for customers in carrying out repairs, maintenance, retrofits, or modifications is a mere fraction of what constitutes successful field service.

Field service management also includes:

- Efficient planning

- Holistic customer management

- Availability of relevant information for and from engineers

- Compiling reports

- Error-free billing of orders

How do Plant Constructors Overcome Their FSM Challenges?

Key Functions of a Field Service Management Solution

- Plan appointments and trips efficiently and transparently

- Generate tickets directly from the system

- Organize service orders efficiently

- Process orders in the field

- Document activities with field data forms, digital signature, and more

- Obtain relevant information relating to customers, machines, and spare parts in real time

- Find expertise quickly and use on site

- Remote support for engineers with augmented reality, smart glasses, or VR goggles

Field Service Management Solution and Spare Parts Catalog

2 Systems – 1 Goal

By introducing a field service management solution, plant and machinery constructors can succeed on all fronts. Anyone already using an FSM solution is already set up for the future. Yet in both cases, the potential for optimization is still significantly underexploited.

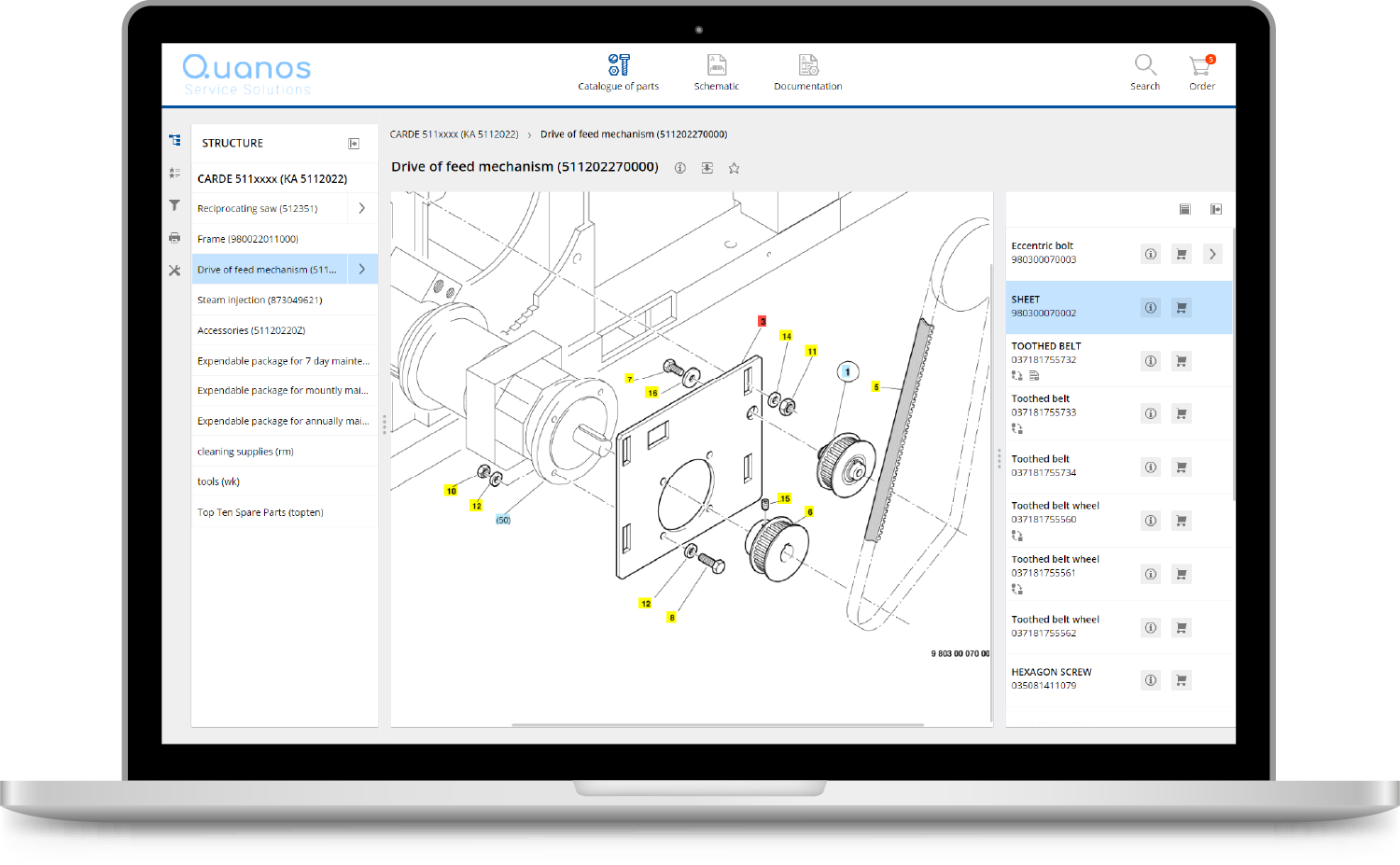

By integrating field service management software with a digital spare parts catalog, not only can service engineers organize all their service orders in real time, they can also identify the spare parts they need in a flash.

The Quanos spare parts catalog, for example, offers a standard interface for integrating field service management solutions from providers such as Innosoft or mobileX (part of Solvares Group).

How do Manufacturers Benefit from an Integrated Spare Parts Catalog?

When working on site, service engineers can access the relevant spare parts catalog simply by clicking in their service report, dispensing with the need for a lengthy search for the right spare part.

In the parts catalog, which can be enhanced with Quanos SIS.one to include various features, engineers will find valuable information, such as parts list entries, images, 2D drawings, 3D graphics, relevant paragraphs from the technical documentation, circuit diagrams, and much more.

Quick identification

of spare parts

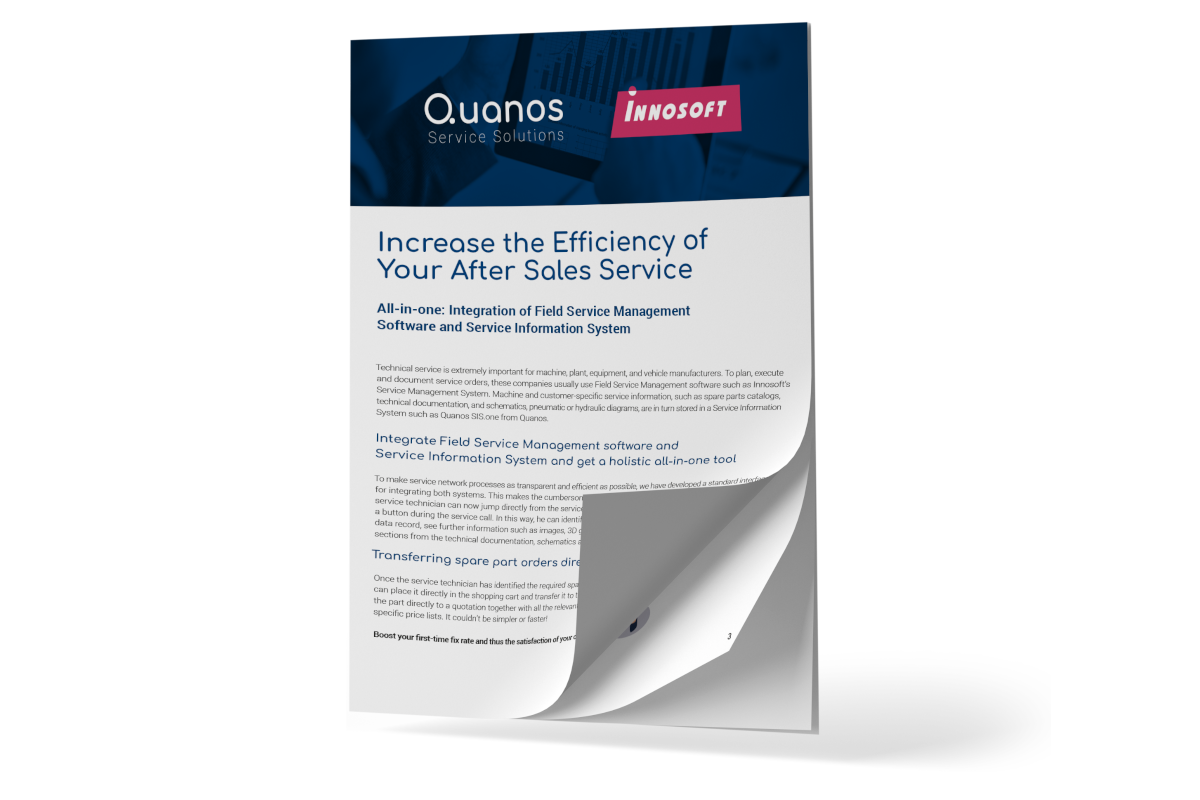

Proven in Practice

Field Service Management Solution with Spare Parts Catalog

Businesses that use a field service management solution for planning and completing jobs, as well as documenting service orders, can effortlessly enhance their whole operation by linking with digital spare parts catalogs, courtesy of Quanos. Kai-Uwe Roiger at Novoferm GmbH is well aware of the benefits that this can bring to day-to-day operations:

„The Quanos spare parts catalog has been in use at our company for quite some time. The successful introduction of the Innosoft Service Management System has not only enabled us to optimize our processes, but we are also benefiting from the synergy effects of its integration with the electronic spare parts catalog.“

Novoferm GmbH Kai-Uwe Roiger | Management

Are Field Service Management and Digital Spare Parts Catalogs Right For Me?

For businesses seeking future expansion of their aftersales service to ensure their growth, both tools are essential.

Find out now whether a spare parts catalog is the right choice for the service challenges you face – watch the free online demo to see the benefits of an interactive parts catalog for yourself.