Sparked interest?

UNTHA

Digital Service Models: For When Your Customer Portal Grows at Record Speed

Austrian machine manufacturer UNTHA relies on digital business models in service. The central hub is the customer portal, which offers numerous features. From alarms in the event of faults to a maintenance planner and an AI-based service assistant, the company is constantly working to develop new digital applications for its machines. With software solutions from Quanos, it can launch these features onto the market faster than ever before.

UNTHA, which has its headquarters in the Austrian town of Kuchl, sells its shredding machines around the world. These shredders, which can be customized to meet customer requirements, are mainly used in waste treatment, resource recycling, and residual wood recycling. UNTHA has a workforce of around 500 employees.

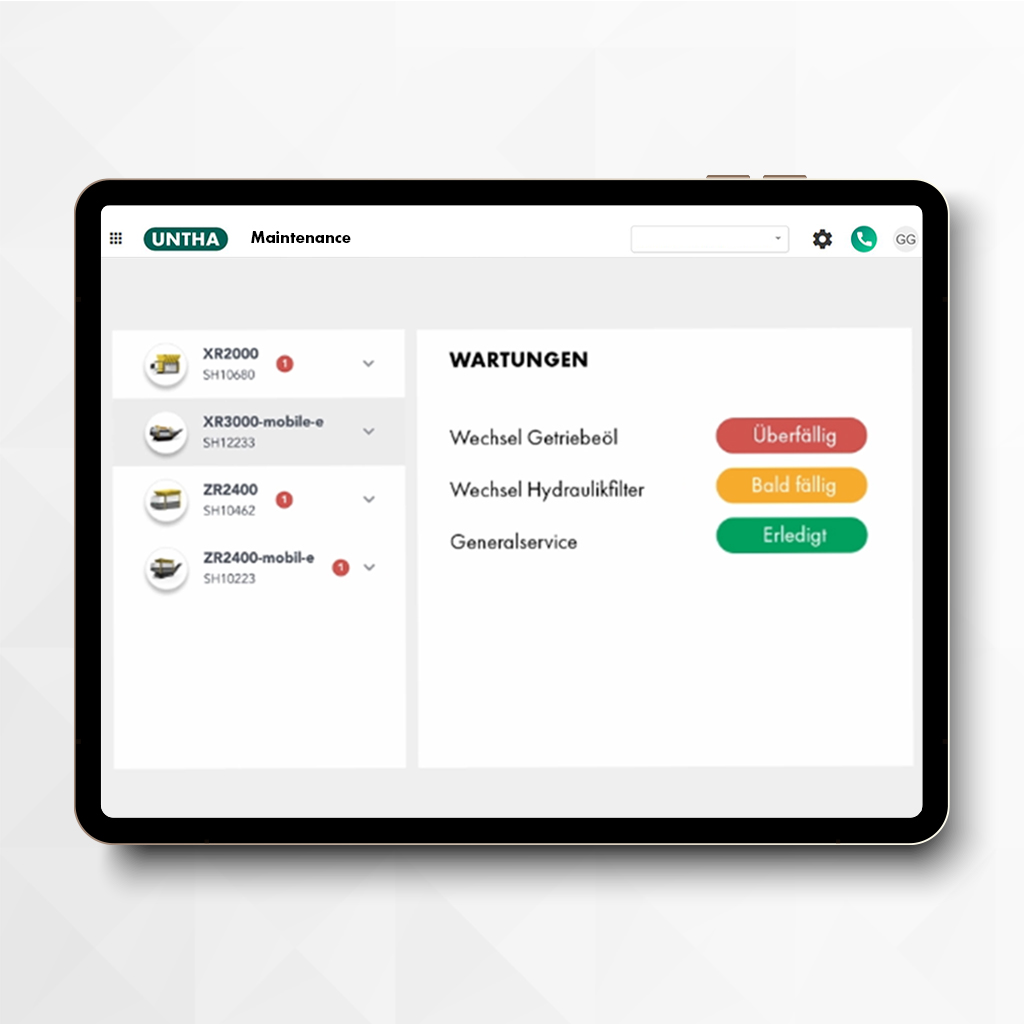

The company is leading the way on the market with its intelligent shredding machines, which are equipped with up to 100 sensors for condition monitoring. Customers can view the real-time data that is collected and processed in the MyUNTHA portal and this enables them to see, for example, how much the machine is utilized or how high the electricity consumption is. Where deviations or faults occur, customers receive alarm notifications with information about the cause and troubleshooting.

Initial situation: inefficient processes delaying the development of digital features

The company previously used a content management system (CMS) to get its alarm messages into the MyUNTHA customer portal. However, the starting point for this was first of all an Excel spreadsheet into which the software development team entered the corresponding messages. Including translation and manual transfer to the CMS, the document had to go through nine stations in various departments before the content was finally available in MyUNTHA. This process took a week.

The workflow was not only inefficient but also became a real bottleneck. For the UNTHA software programmers, who are responsible for adding new features to the customer portal, it was taking much too long for new content to be added or changes made; each time they had to wait days for new test data to be available. The upshot? This held up the market launch of new digital offerings.

The solution: a direct line between the content management system and the customer portal

The solution to the problem was not too far away as the UNTHA technical writing department was already working with SCHEMA ST4 content management system. So why not use this tool to transfer the alarm messages to the customer portal? The machine manufacturer chose to rely on another piece of Quanos software for this project: the InfoTwin content delivery system. This modular cloud solution was used to connect the content management system to the MyUNTHA customer portal. The technical implementation of the connection was completed in just one week.

The new solution significantly shortened the whole process from the drafting of new alarm messages to their publication. The alarm messages are still written in the software development team but they are imported directly from there into SCHEMA ST4— the Excel spreadsheet is now a thing of the past. The technical writing department then carries out the task of sending new alarm messages for translation via a COTI interface. Once the messages have been translated correctly, a technical writer releases the alarms from ST4 for InfoTwin.

Publication in a matter of hours instead of a week

The customer portal automatically retrieves new data from InfoTwin every 15 minutes, meaning that the content no longer has to be manually copied into the web interface of a content management system. Altogether, it has been possible to shorten the whole process from at least a week to one day at the most.

“For us, the most important thing is not how much working time we’re saving in a year, but how quickly the process takes place,” says Georg Grünwald, AI Architect at UNTHA. In software development, employees use agile project planning methods and work in two-week sprints. “Each sprint incorporates all the experience from the previous sprint, which is why it is important that any necessary changes are implemented quickly. The optimized process has made such a difference here.” Prior to the changeover, the team at UNTHA would often have to wait for half a sprint before they could continue their work.

Benefit: shortened time to market for digital offerings

The Quanos software solutions that are optimally harmonized with one another not only allow UNTHA to add alarm messages to its own customer portal more efficiently today, but also enable it to create numerous new digital offerings in next to no time. For example, UNTHA developed a maintenance manager that is available via the HMI display and the customer portal in the space of just eight months. This tool informs customers about upcoming maintenance and displays step-by-step instructions. The content originates from SCHEMA ST4. “Normally it takes 18 months to two years to bring this kind of feature onto the market,” says Georg Grünwald. According to him, the connection from SCHEMA ST4 to the customer portal was instrumental in the tool’s rapid development.

On the horizon: AI-based service assistant already in the planning stage

The plan is for InfoTwin to serve as a single source of truth for maintenance documentation at UNTHA in the future. Additional features are already being developed. Customers will very soon be able to access maintenance and operating instructions via a QR code. The company hopes that this development will avoid printing, save costs, and contribute to greater sustainability.

“We are currently developing an AI-based service assistant that will support our internal service team and later our customers too,” explains Georg Grünwald. The assistant provides responses based on content in SCHEMA ST4 Content Management System.

Conclusion: a versatile and modern customer portal with software solutions from Quanos

InfoTwin allows content from the content management system to be published in the MyUNTHA customer portal in no time at all—with no copying & pasting or manual comparison of Excel entries required. Where before at least one week’s notice was required, now new content is available in the customer portal in a matter of hours. This is made possible through the connection of the SCHEMA ST4 content management system with UNTHA’s customer portal via InfoTwin.

“The systems complement one another perfectly and this enables us to use an efficient management solution,” says Georg Grünwald. “Our workflow has also improved considerably as a result and our team can work much more efficiently. The data quality is also consistent. InfoTwin means we have the flexibility to connect additional systems to ensure we have the same information available everywhere. These optimizations have significantly shortened the time to market for our digital offerings.”

UNTHA shredding technology

„SCHEMA ST4 and InfoTwin are the perfect solution for machine manufacturers. We have been able to significantly increase our efficiency and have created a seamless workflow where technical documentation supports software development. This enables us to publish information more quickly than before and implement digital projects rapidly. The solutions from Quanos are also future-proof and make it very easy to connect external systems.“

Mechanical and plant engineering