myPlant* - The Digital Information Twin from INNIO for gas engines

With the cloud-based technology myPlant*, customers of gas engine manufacturer INNIO can manage their plants from anywhere, securely and in real time. Via remote access to their machine's Digital Information Twin, customers can control the operational performance and profitability of their gas engines and benefit from unprecedented insight into the performance of their industrial plants.

INNIO's myPlant* solution improves plant availability and efficiency and reduces total life cycle costs.

*myPlant refers to a trademark

myplant* - Successful KPIs

remote monitoring, diagnosis and analysis

available analysis parameters

remote

fix rate

connected sensors for monitoring

data collected

per year

connected

system

The Digital Information Twin machine data to humans

Unlike the Digital Engineering Twin, the Digital Information Twin delivers data to people. Where the Engineering Twin is used, data is exchanged between machines. Here, the exchange of data in real time is particularly important.

With Digital Information Twin, on the other hand, the greatest possible variety of information is more important in order to provide people with a detailed picture of their machine.

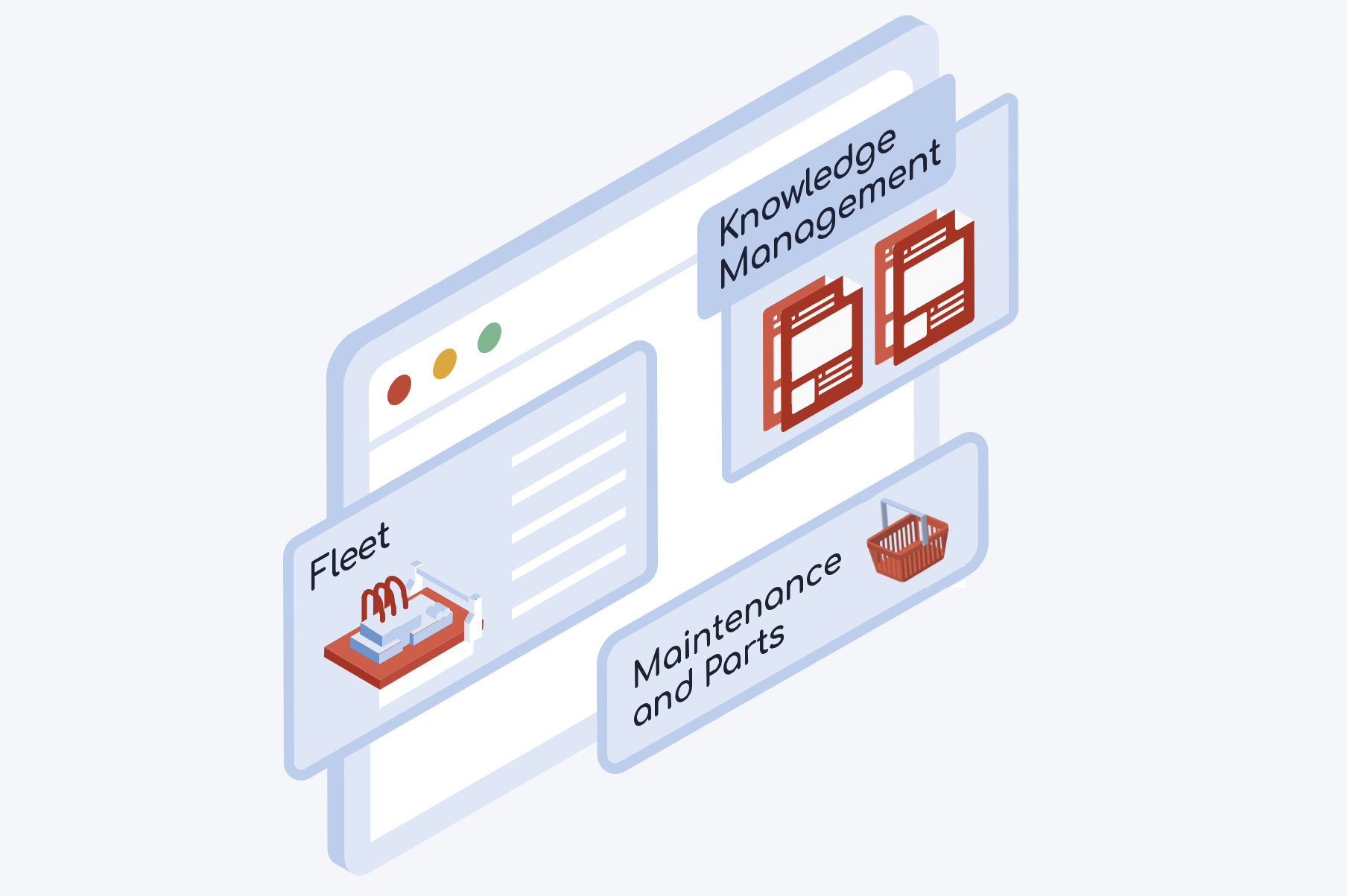

The components of myPlant*

For a functional Digital Information Twin INNIO has combined all necessary components for a holistic system package.

With this package myPlant* provides the single source of truth for the machines integrated into the system. This means that the combined software solutions maintain a single valid database. Explore the diagram on the right for the central solutions within myPlant* and their tasks.

Introducing INNIO Jenbacher

INNIO is a leading solution provider of gas engines, power plants, the digital platformmyplant as well as complementary services in the field of power generation and gas compression close to the consumer.

World-wide INNIO cares for more than 48,000 so fardelivered gas engines over their entire service life. Supported by a broad network of serviceproviders INNIO is represented in more than 100 countries.

__________________________________

Innio facts & figures

gas engines in field

capacity

countries

INNIO about Quanos

"At Quanos we go even further"

Thanks to its versatile components, Quanos offers a more modular range of solutions, which in future will be available as a bundle for 360-degree coverage, but can also already be purchased individually.

The services can either be booked as a cloud service or alternatively operated "on premise" within an organization. The Quanos Group's aim is to offer upwardly compatible services.

Our aim is to offer our market the single source of truth with the Quanos Digital Information Twin. Our aim is to provide a data model in which a generally valid data set is made available. Our offer is primarily aimed at the after-sales and service area of our customers.