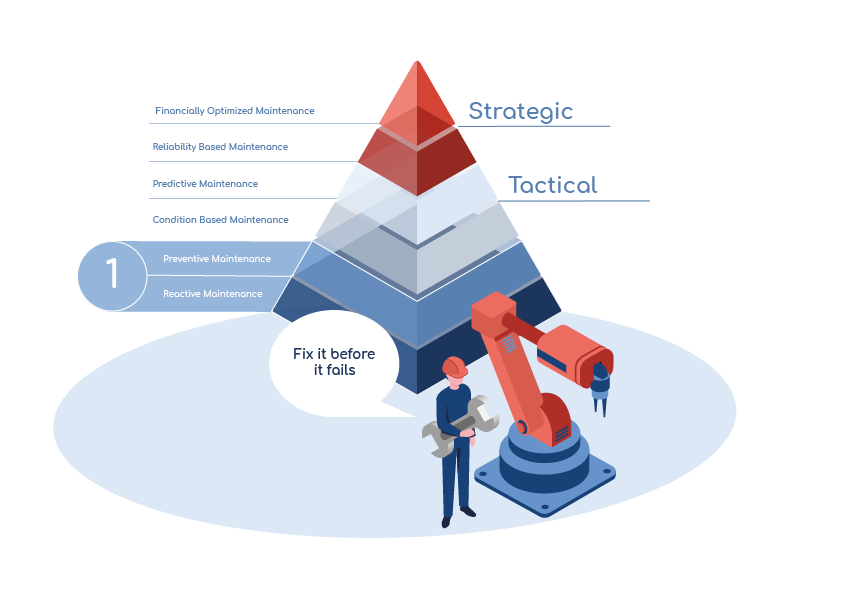

Preventive Maintenance: From Repair to Prevention

After Reactive Maintenance, Preventive Maintenance is the second level of the maintenance pyramid. In the simplest case, this requires practically no implementation effort, just a bit of planning: The maintenance and preventive replacement of parts is scheduled based on uptime or usage.

Preventive Maintenance as a precautionary method

Preventive maintenance is what is done on a car, for example: The timing belt, for example, has to be replaced every 120,000 kilometers or 6 years - the manufacturer has found out in tests and calculations that practically all timing belts reach these intervals without breaking. So the timing belt is replaced at a time when it is still functional in virtually all cases. If you just keep driving, the risk of a broken timing belt and thus engine damage increases more and more.

Minimal downtime and moderate costs

Replacement by interval can be planned so that downtime is kept to a minimum and maintenance costs are very moderate compared to those incurred in the event of equipment failure. Moreover, in this maintenance strategy, the spare parts inventory can be planned very well. Preventive maintenance always keeps the machines in good condition and unexpected equipment failures should be relatively rare. The need for spare parts for preventive maintenance can also be predicted quite well based on planning, so that the required parts are always in stock in sufficient quantities.

Finally, logistics can be better planned - some parts cannot necessarily be shipped by parcel service but require forward planning that takes delivery time into account.

To quickly identify the right spare or wear part, maintenance staff need a digital spare parts catalog with extensive search options. The technical documentation linked to the respective spare part with repair, maintenance and installation instructions helps to install the spare parts.

Next step: Tactical maintenance

From operational maintenance in the first two evolutionary stages of the maintenance pyramid, we move on to the area of tactical maintenance. This is divided into the stages Condition Based Maintenance and Predictive Maintenance. In the next blog post, you will learn more about the benefits of these two maintenance strategies.

To return to the previous level of the maintenance pyramid, click here.

More information about tactical maintenance and strategic maintenance you find here.