Skilled workers are hard to find, while existing teams have to work through ever more tasks in less time. In order to remain effective and competitive, service teams should therefore find answers to the following questions as quickly as possible:

- Experienced service technicians are retiring – how do we preserve their knowledge?

- Service call-outs take too long – how do we achieve greater efficiency and avoid expensive incorrect orders?

- The first time fix rate is too low – how do we improve the quality of the service call-outs?

- The pressure to digitalize is growing – how do we digitalize and optimize our processes?

- Our customers’ demands are increasing – how do we still offer them excellent service?

- Customers expect short downtimes – how can we respond more quickly to inquiries and complete jobs more efficiently?

Service managers need to solve all of these challenges. The biggest lever for this is increasing service productivity. But the resources and financial means for the necessary improvements are limited.

See for yourself

Videos contain English subtitles

The way to improved service productivity with the same number of team members is through digital platforms. They simplify existing processes by providing support and service employees with all the information they need to achieve excellent results.

With a digital service platform which, for example, offers intuitive step-by-step instructions, your service employees can fulfill more customer requests in the same amount of time and significantly increase their productivity – as well as customer satisfaction.

Modern service teams in machinery and plant construction rely on digital information twins for this. A digital information twin (DIT):

- Serves as a central platform for technical information and service information about a product, machine, or plant

- Bundles and synchronizes data and therefore creates an integrated information management system that fulfills different functions

- Saves service engineers, service technicians, maintenance staff, and other DIT users the hassle of searching for spare parts information and maintenance instructions. Instead, all information for their maintenance tasks can be accessed quickly and digitally via an intuitive user interface

- Speeds up service call-outs and ensures that more call-outs per week can be carried out

- Is the basis for trends such as predictive maintenance

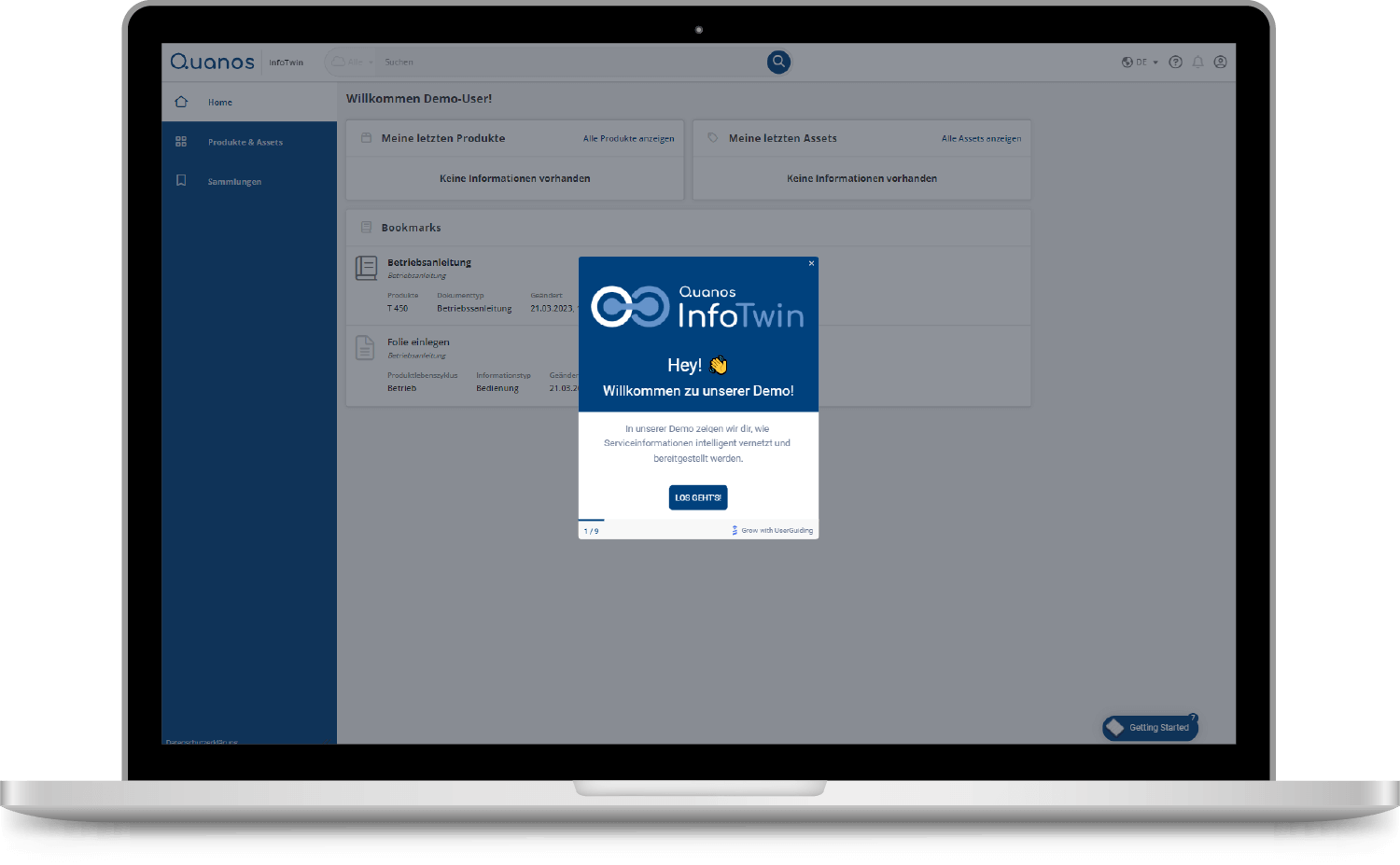

If you want to increase your team’s productivity without any effort and digitalize your processes, Quanos InfoTwin is the key.

Everything that your service technicians need to improve productivity is available to them in Quanos InfoTwin via an intuitive interface – worldwide, 24/7, and on any device.

Quanos InfoTwin is:

- The standardized cloud solution from Quanos for service teams in machinery and plant construction.

- An aftersales platform which is immediately ready to use, with the possibility of modular expansion.

- A tool that aggregates and networks all relevant information for the aftersales and service process into a digital information twin.

- The basis for new business models and smart services.

- A networking tool for the entire aftersales area which offers a wide range of functions and flexible integration and expansion options.

- A platform that places the focus on the status of a product using an asset-based overview of individual products.

Quanos InfoTwin connects different data sources and makes all information clearly available for your service technicians. A smart service wizard ensures an even better overview and greater speed. Find out what this means for your service quality in detail.

With Documentation & Knowledge, Spare Parts, and Service Activities, Quanos InfoTwin offers a strong trio of functions for service teams. These three capabilities are ideal for getting started with your service optimizations and can be expanded as desired.

Spare Parts: Efficient spare parts management

The search functions in Quanos InfoTwin make identifying necessary spare parts easier. It is possible to order parts directly from the system and without uncertainty about whether the spare part is really the right one. This reduces the number of incorrect orders and the additional costs that are generated as a result.

Benefits of the Spare Parts Capability:

- Visual identification of spare parts with interactive 2D drawings and 3D models

- Display of linked spare part bill of materials with all key information

- Navigation through the product’s assembly structure

Documentation & Knowledge: Networked information

Quanos InfoTwin networks all information that service technicians need and offers access to product-related documentation. To help your team maintain an overview, the platform automatically networks information and makes it searchable.

Benefits of the Documentation & Knowledge Capability:

- Central information basis for all your product information

- Digital information twins of your products in the cloud, which can be accessed anytime and from anywhere

- Automatically networked information from different sources, for example, from third party systems

Service Activities: Step by step to more productivity

Quanos InfoTwin offers guided step-by-step instructions that help your service technicians to prepare efficiently for a call-out and carry out their work in the best possible way. This means that you can achieve more with the same team and make yourself less dependent on the shortage of skilled workers.

Benefits of the Service Activities Capability:

- Interactive step-by-step instructions for maintenance and servicing

- Additional information about spare parts, tools, or wear parts

- Overview of the activities that have already been completed

Get to know the Quanos Digital Information Twin

With the Quanos DIT platform, your service technicians will find exactly the information they need on site to quickly eliminate a fault, thus allowing them to work more productively.

See for yourself the advantages of the platform for greater service productivity, lower costs, and more satisfied customers.