Three editors manage 4,000 documents for 100,000 product variants with SCHEMA ST4

Of the 22 technical writers at SEW-EURODRIVE, three editors deliver 4,000 customer-specific instruction manuals for a particular product line every year. That’s an average of 11 manuals a day. For a product portfolio that contains over 100,000 variants, is this even possible?

As Anne Kuhsen from SEW-EURODRIVE showed us at the SCHEMA Conference: Yes, it is! But to do so, you need a high-performance CMS and to consistently harness the power of automated authoring processes. Here you can read once again how SEW-EURODRIVE meets this challenge with our SCHEMA ST4 component content management system.

Global player with a large portfolio

For nearly 90 years, SEW-EURODRIVE has been at the forefront of the drive technology industry. Whether luggage conveyor belts at airports, bottling plants in the beverage industry or drive components in container cranes: wherever something needs to be moved to industrial standards, the drive technology of SEW-EURODRIVE can often be found hard at work in the background. Seventeen thousand employees in 50 countries and a global turnover of more than 3 billion euros testify to the success and market presence of the family-run enterprise from Bruchsal in Baden-Württemberg, Germany.

The product portfolio is just as diverse, containing classic products such as gearboxes, geared motors or servo drive technology and modern solutions for industrial communication, control technology or energy transmission.

The challenge: 100 percent customer-specific manuals

Apart from all the usual challenges in modern technical writing, the editorial staff at SEW-EURODRIVE is faced with one very special aspect: customers are generally given individual instruction manuals for a specific product range, which exactly match the content of the product ordered right down to the special configuration. This is no mean feat when you consider that the number of possible product variants totals 100,000.

At SEW-EURODRIVE, the need for 100 percent individualised instruction manuals is also due to the ordering process. A sales representative assembles the desired product for the customer in the product configurator, where they can select individual features such as the design of the drive shaft or the space required. For the technical writers, this means it is not possible to predict which version of a manual will be needed next.

Process automation via the SCHEMA APX module

In her presentation at the SCHEMA Conference, Anne Kuhsen presented the two-stage concept with which the technical writers at SEW-EURODRIVE master these requirements.

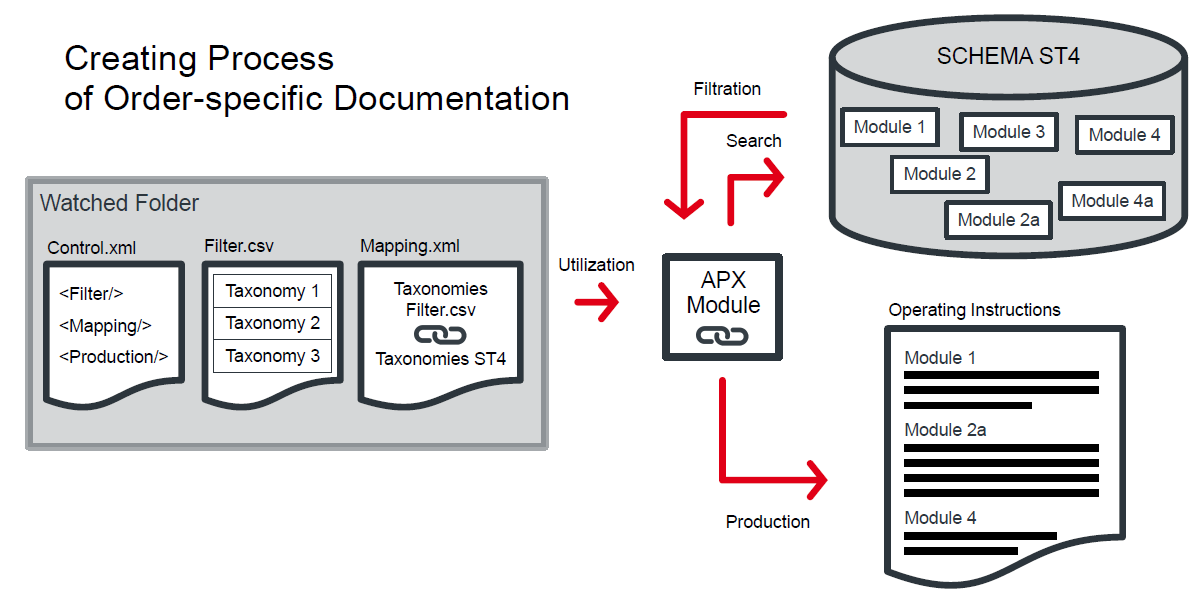

As part of this concept, SCHEMA ST4 is integrated as a component content management system in the automated order processing workflow at SEW-EURODRIVE. When a sales representative configures a product for a customer order, SAP forwards the order’s documentation-relevant data in the form of control files to the SCHEMA ST4 APX module. This automation component automatically identifies the content components required for the manual and initiates the generation of the corresponding document – again without the intervention of a writer.

Data in SCHEMA ST4 optimised for “self-service”

The fact that the automated document creation process can be “simply” carried out by SCHEMA ST4 as a component content management system requires a special form of data management.

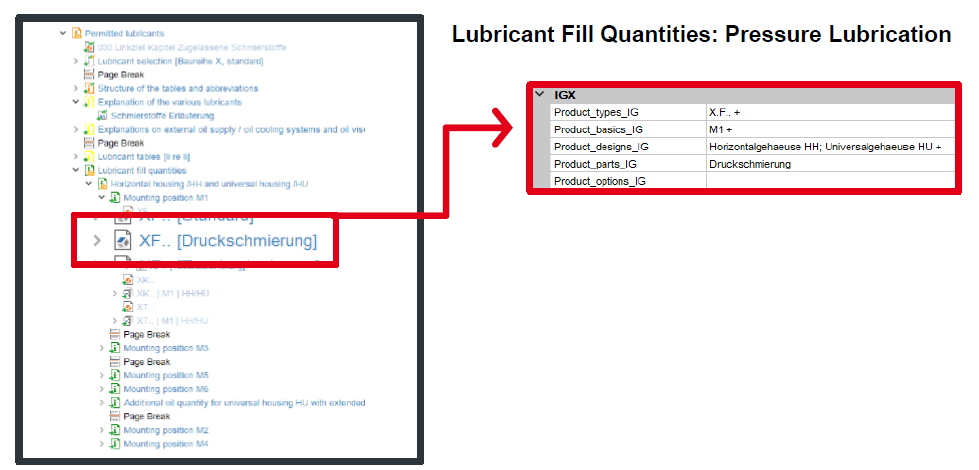

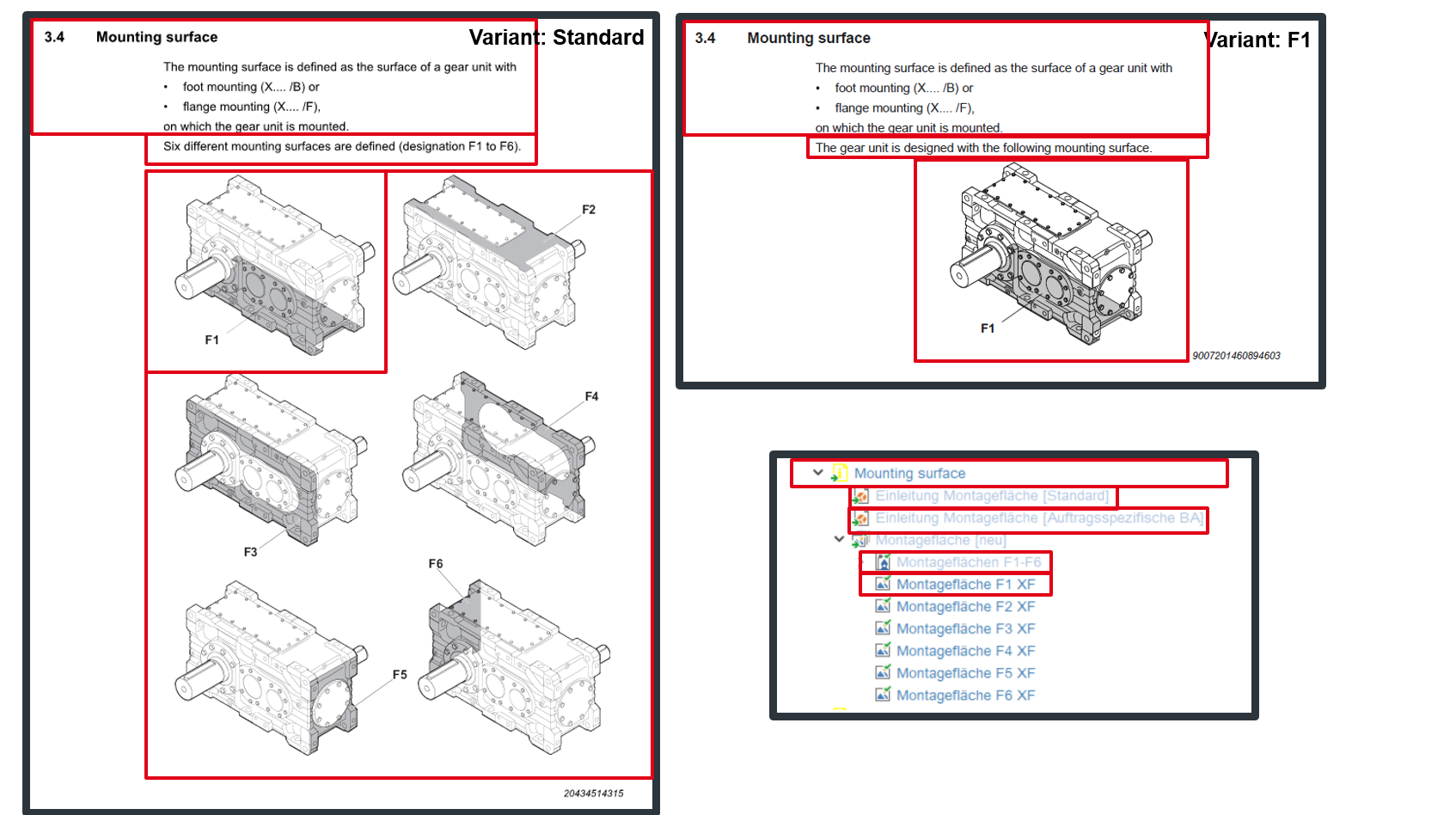

It is necessary to establish a correspondence in the CMS between the modularity of the products and the modularity of the components in ST4. The components in ST4 must then be labelled with the aid of metadata and taxonomies in such a way that they can be clearly assigned to the products for which they are valid. Both requirements can be easily implemented with the standard configuration of SCHEMA ST4.

In order to “assemble” the components into documents, SEW-EURODRIVE has chosen a so-called “maximum document” solution. But what is behind it?

In ST4, there is a document that contains all the components for all product variants of the specific product range. When creating a customer-specific document, filter mechanisms ensure that only the relevant components find their way into the respective manual. And as we have already discussed, this process is completely automated.

What is your need?

SEW-EURODRIVE is certainly not the only company that needs an efficient editorial solution for the ever-greater differentiation of the product portfolio. How about you?

If you are still working without a CMS: The example of SEW-EURODRIVE shows in a very demanding application how our component content management system optimally supports you in the area of variant management.

Do you already use SCHEMA ST4? Then many of the mechanisms used by SEW-EURODRIVE are already at your disposal. You therefore have the tools you need to develop your technical writing process in a way that allows you to harness the possibilities of automation.

About Anne Kuhsen

Anne Kuhsen studied Technical Communication at the University of Applied Sciences Karlsruhe and has been working for SEW-EURODRIVE GmbH & Co. KG for over 10 years. She is an ST4 administrator since 2011 and was in charge of the transition from a highly customized ST4 version to the standard version. In addition, she continuously develops concepts and methods for process optimizations and their integration in ST4. Since 2017, she also heads one of SEW’s editorial teams.