Frustration in the service department costs time and money

In the past, most of a manufacturer's work was done with the sale of the machine and plant. Today, the sale of a machine is just the start. This poses major challenges, especially for the aftersales and service sector.

Maximum efficiency is demanded from the teams that ensure processes run smoothly for operators. On the one hand, this is because machinery and plant manufacturers have to save money. On the other hand, they need to find ways to fill gaps left by the shortage of skilled workers and retiring experts.

There are usually precise ideas about how this is to be done. However, expectation is often far from reality:

Reality:

- Problems identifying spare parts

- Queries to the service hotline due to uncertainties and unavailable information

Reality:

- Complex machines and spare parts make identification difficult

- Information is distributed over several systems and often outdated

- No central ordering option

Reality:

The necessary information basis is not available – often there is not even access to the descriptive documentation while on the go

Reality:

Required parts are not fully and centrally documented, service call-outs therefore often have to be planned again

Reality:

Information about various machines spread out over several systems slows technicians down

Reality:

No remote access to necessary information and lack of a central database for past call-outs

Reality:

Lack of processes for structured knowledge transfer

The prerequisites for better prepared, efficient call-outs are transparency, overview, and digital processes. All of this is made possible by a digital information twin.

A digital information twin (DIT) is a platform that connects the technical information and service information about a product, machine, or plant. The data is centrally stored and synchronous in the DIT.

This results in an integrated information management system that fulfills different functions. The DIT:

- Displays the real status of a product – from the first day it was used

- Puts the spotlight on the product's entire life cycle

- Contains information about spare parts, documentation, and manuals for a certain machine or variant

- Provides service engineers, service technicians, maintenance staff, and other DIT users with all the spare parts information and maintenance instructions that they need

- Provides relevant information for maintenance tasks – quickly, digitally, and via an intuitive user interface

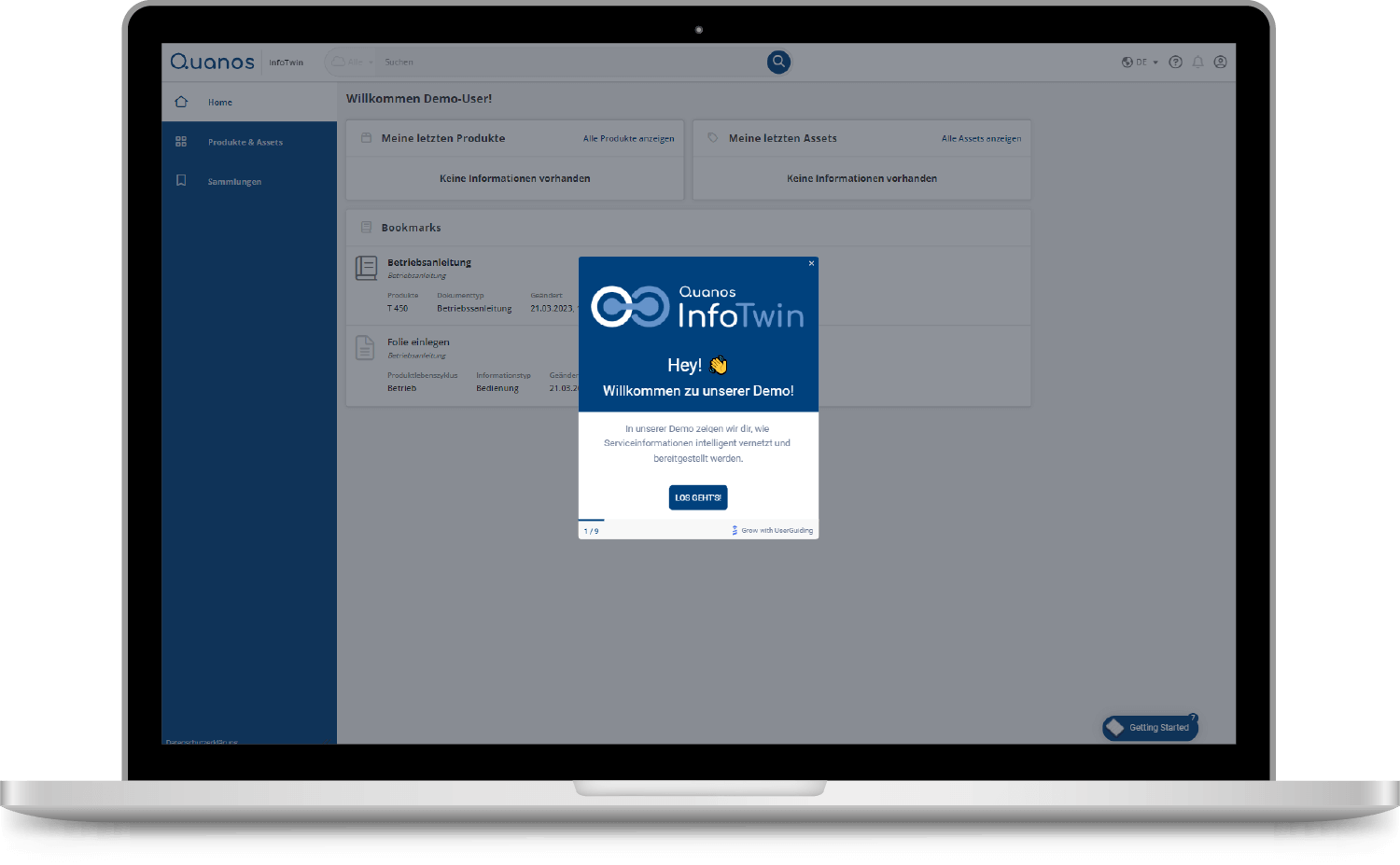

See for yourself

If you would like to fulfill the most urgent needs of your service team and help technicians to achieve greater efficiency in their day-to-day work, Quanos InfoTwin is the key.

Quanos InfoTwin is a platform that supports service teams with planning, preparing, and carrying out efficient service call-outs by providing relevant information and intuitive step-by-step instructions – regardless of when and where your service technicians are needed.

Quanos InfoTwin is:

- The standardized cloud solution from Quanos for service teams who want to work in a modern and efficient way.

- An aftersales platform with the possibility of modular expansion for even more efficiency.

- A digital information twin in which all relevant information for the aftersales and service process is aggregated.

- The basis for new business models and smart services.

- A networking tool for the entire aftersales field which can be flexibly integrated and expanded.

- A platform that places the focus on the status of specific products.

Spare Parts: Identify spare parts more efficiently

- Convenient search functions

- Efficient identification of the spare parts required using interactive 2D drawings and 3D models

- Display of the linked spare parts bill of materials including order function

- Navigation through the product’s assembly structure

Documentation & Knowledge: Find information more efficiently

- Access to product-related documentation

- Networked and searchable information from different sources, for example from third party systems

- Central information basis for all your product information

- Digital information twin of your products in the cloud

- Information can be accessed at any time and from anywhere

Service Activities: Carry out jobs more efficiently

- Instructions and warning notices from technical documentation are available in the form of interactive step-by-step instructions

- Completed tasks can be checked off to provide a greater overview

- Additional information on all activities, such as spare parts, tools, or wear parts

- Service wizard provides information about upcoming tasks for efficient preparation and execution of jobs

- Transparent overview of the activities that have already been completed

Get to know your new efficiency boosters

With the Quanos DIT platform, your employees can prepare for and follow up each call-out optimally as well as carry out maintenance and modifications more quickly.

See for yourself what advantages the platform offers for the efficiency of your service team and how you can use it to reduce costs and increase customer and employee satisfaction.