There is pressure on machinery and plant manufacturers as costs are rising while turnover from new machines has been falling for years. Customers want the highest level of performance and service instead of new machinery.

Aftersales teams are the biggest rays of hope when it comes to remaining competitive. However, aftersales managers – whose mission it is to boost stagnating sales and ensure customers are satisfied – face several challenges. They have to

- optimize sales of services and spare parts

- offer new services to generate additional sources of revenue

- provide all relevant aftersales- and service information centrally and integrate it intelligently, as their area is becoming increasingly complex and data-driven

- break up data silos so that their team can work more efficiently

- improve customer loyalty by offering services focusing on specific machinery, for example

- save their team and their customers time by using digital processes and self-service portals

Today, aftersales and service count among the most important factors in a company’s success. The goals are clear – but how does your team achieve them? The answer lies in digital processes and a platform that can be used to centrally control measures for increasing success.

Whitepaper reading tip

Next-Level Service: How Machine Manufacturers Stay Successful

Success strategies for digitalizing and marketing aftersales services.

One reason for increasing complexity in mechanical and plant engineering is digitalization. But it also holds the key to efficiently tackling this issue – for example, in the form of digital information twins for aftersales & service.

A digital information twin (DIT) is the digital model of your aftersales- and service information. It serves as a central information platform, with which you can

- intelligently link technical information and service information about a product, a machine, or a system.

- bring together and synchronize relevant data for your employees and customers to create an integrated information management system that simplifies the work of all those who use it.

- create a comprehensive information base for optimizations in aftersales & service.

- lay the foundation for developing new, customer-focused services, and therefore greater competitiveness.

- improve the profitability of your service- and sales activities to achieve higher turnover in aftersales and service through optimized sales of spare parts.

A DIT provides you with an intelligent data model of your machinery and plant, which offers far more than a virtual representation of reality. This is because the data in the platform are prepared and integrated in a way that allows users to more easily leverage sales potential.

The smart way to achieve higher turnover: Quanos InfoTwin

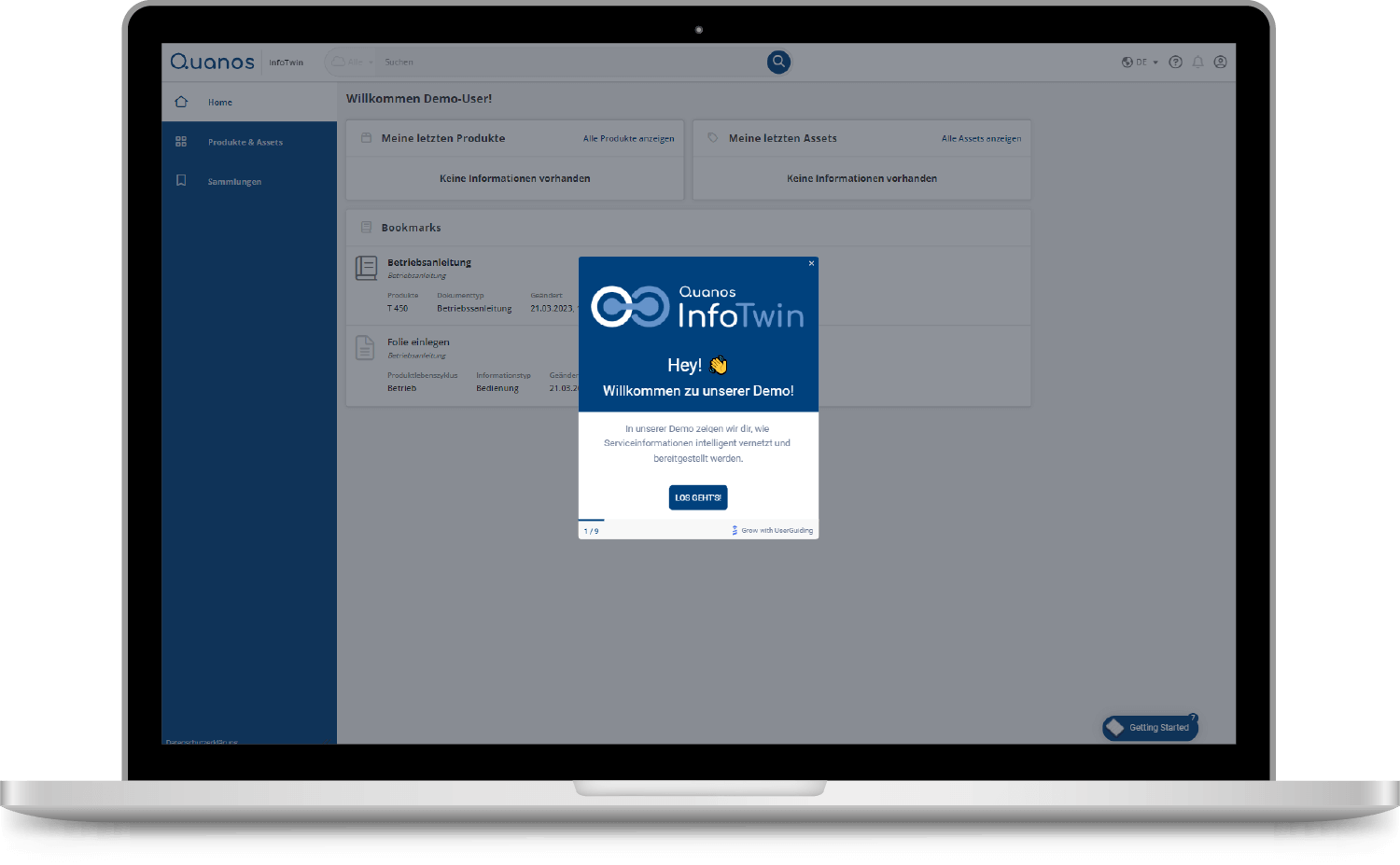

Quanos has developed a digital information twin especially for machinery and plant manufacturers: Quanos InfoTwin. It helps aftersales and service teams achieve their sales objectives.

Quanos InfoTwin is a standardized cloud solution that

- can be used straightaway as an aftersales platform and expanded with additional modules.

- aggregates all relevant information for the aftersales and service process into a digital information twin and intelligently integrates the data.

- provides an indispensable basis for developing new business models and smart services – for example, you can use it to implement operator models, which more and more customers are requesting.

- offers a wide range of functions and flexible integration and expansion options for the entire aftersales area as a networking tool.

- places an asset-based focus on individual products, thereby highlighting the status of a product.

If you want to be perceived as a strong service partner for operators after they've purchased your machinery and systems, then Quanos InfoTwin has everything you need.

Empower your aftersales team to deliver their best performance with an intuitive interface, regardless of which device they're using, and information that's available around the world at any time.

How to use spare parts and smart services as sales drivers

Usually, the information that can provide companies with significant sales advantages is already available. Quanos InfoTwin provides this to aftersales & service teams in one central location and offers three overarching capabilities to obtain everything from the data.

Quanos InfoTwin contains a strong trio of tools for aftersales and service teams to optimize their services. The Documentation & Knowledge, Spare Parts, and Service Activities capabilities resolve three major challenges: They simplify spare parts ordering, relieve the strain on customer support teams, and improve the service experience.

Spare Parts: Boosting spare parts sales and customer satisfaction

The easier it is for customers to find and order spare parts, the quicker your turnover will grow. Quanos InfoTwin features intelligent search options and an interface that transfers spare parts directly to a shop system where the customer can complete the order process.

Give your customers the option to

- identify spare parts visually using interactive 2D drawings and 3D models.

- access linked spare part bills of materials.

- complete their purchase more quickly, while also discovering other services and spare parts kits.

Documentation & Knowledge: Bringing together information

Efficiency and transparency are key prerequisites for better service and increased sales. Quanos InfoTwin brings together all the information needed for aftersales and service from different sources in one place.

Create a central information basis with modular content that can be accessed from anywhere, at any time via a browser and is easy to search.

Service Activities: For satisfied customers

With Quanos InfoTwin, you can provide your customers with interactive, step-by-step instructions that also simplify the work of your service engineers.

This must-have content gives you good sales arguments, allowing you to monetize access to information. At the same time, it saves your support teams time and effort.

Offer your target groups:

- Maintenance and servicing support

- Additional information about spare parts, tools, or wear parts

- Up-to-date, tailored service documentation

- A sound basis of knowledge on which business models and smart services can be established

The DIT from Quanos puts the focus on your products and shows all information available from technical documentation, spare parts catalogs, CAD data, 3D models, ticket and shop systems.

With the addition of functions such as field service management, overall equipment efficiency, or asset performance management, you have a digitalization tool for all your aftersales needs that easily allows you to tap into new sources of revenue:

- A Twin API enables data to be made available with ease so that you can create digital value-added services.

- Analytical information on assets forms the basis for new business- and accounting models like SaaS or subscriptions.

- Quanos InfoTwin is modular, meaning new functions and services can be added as desired. You can therefore offer your customers additional services and information at any time.

You do not yet have your own online shop and want a quick and easy way to tap into successful e-commerce?

Then GÉNIE for InfoTwin is just right for you! The e-commerce extension for Quanos InfoTwin is specially optimized for mechanical engineering and the manufacturing industry. It opens the world of InfoTwin towards real e-commerce.

The shop system is connected to Quanos InfoTwin via a special shop connector for bidirectional data exchange – creating a seamless connection between the world of spare parts catalogs and e-commerce.

Get to know all the functions and advantages of Quanos InfoTwin

The DIT from Quanos offers aftersales teams everything they need to achieve their next jump in sales: an overview, relevant information, and an easy way to tap into new business models.

See for yourself what opportunities the platform can open up to your aftersales team.