Interest aroused?

You would also like to implement an aftersales project?

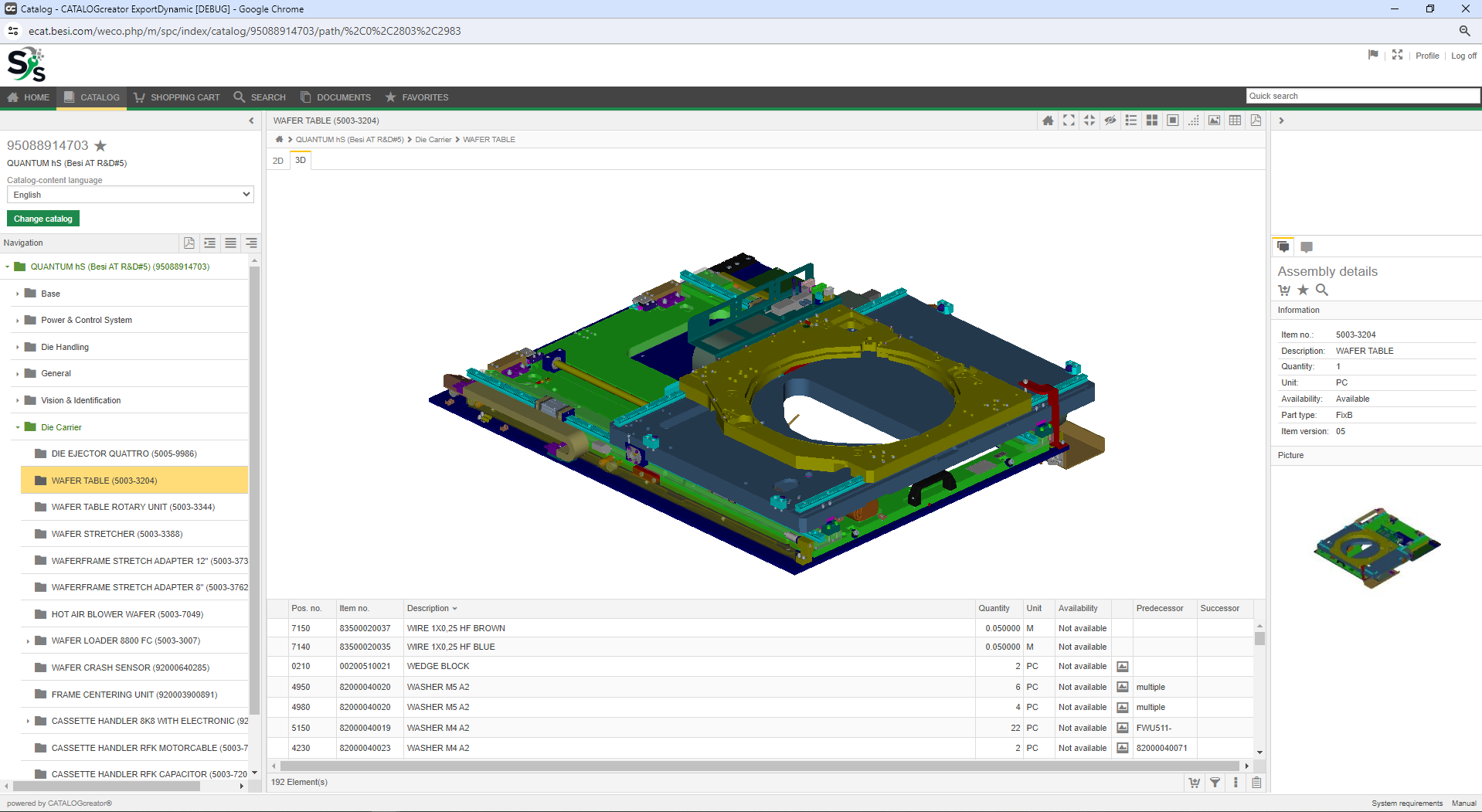

Semiconductors are a key component of digitalization, the production of which requires reliable machines such as those built by BE Semiconductor. Using Quanos SIS.one, the machine manufacturer from the Netherlands has successfully digitalized its spare parts catalog to ensure that service runs smoothly.

BE Semiconductor, or Besi for short, has been developing and producing machines for the semiconductor industry since 1995. In addition to its head office in Duiven, the Netherlands, Besi has development and production sites in Europe and Asia.

Today, the company has over 1,900 employees and is regarded as one of the leading suppliers of assembly equipment in the key markets. Besi's customers include OEMs such as Qualcomm and Samsung, suppliers such as Foxcon, and semiconductor manufacturers such as Bosch, Infineon, and TSMC.

Besi's portfolio includes systems for die-attach processes, packaging, and coating. The machines produce important components for digitalization and for this reason, precision, efficiency, and smooth processes are required for all tasks. Easy identification and the quick availability of spare parts play a crucial role here.

In the past, spare parts information was available to the machine manufacturer's customers in the form of PDF catalogs or 3D spare parts catalogs. The 3D spare parts solution used required a 3D plug-in, which is now an end-of-life product and no longer works with all operating systems and browsers. The manufacturer's growing product range also presented increasing challenges for the system.

Frank Goller, Director Spares and Tooling at BE Semiconductor, explains: “At one point we were faced with the task of mapping 150% product catalogs and 100% serial number catalogs, as well as providing an increasing amount of raw data for the spare parts catalogs. Our old system was no longer able to cope with this volume of data.”

What's more, just like for their customers, the topic of digitalization was on the agenda for the BE Semiconductor aftersales team. The introduction of digital spare parts catalogs that can be integrated seamlessly into the existing spare parts online store was therefore in the pipeline.

“With the digitalization of the catalogs, we wanted to reduce the workload involved in catalog creation and support, and give our customers an aftersales service with added value,” says Frank Goller, mentioning other important challenges related to the spare parts catalogs.

Frank Goller took over project management for evaluating and implementing a new spare parts catalog system that is up to the challenge. As part of a tender and with the support of an external consulting firm, he put several providers to the test.

“Our new system had to be able to process 3D data and information on various product areas. The connection to our online store was also a must.”

The company opted for Quanos SIS.one. “With Quanos SIS.one, we can create our spare parts catalogs from CAD data and make them available online and offline. Previously, labor-intensive manual work was required to create 2D graphics, and thanks to Quanos, this can now be automated. The system is also so intuitive that you don’t need really specialized knowledge to create catalogs,” says Frank Goller, summing up the most important reasons for the decision.

Even during the implementation phase of the spare parts project, it became clear to the Director Spares and Tooling that he had made the right choice: “The Quanos team implemented the project competently and in partnership with us, and I always enjoyed working with them.” He adds: “The team made sure to cater to our needs. For example, it was important for us to carry out the project in English, as our site in Singapore was involved.”

Thanks to Quanos SIS.one, catalog creation is now fully automated, with the process being managed in PLM. From there, parts lists, the material master, and 3D data can be published in jt format, and the relevant documents added. Besi hosts both the test and live system.

Quanos SIS.one is integrated into the company's online store with a shopping cart interface, which means that customers can query things like the availability of spare parts themselves. The spare parts catalogs are also used internally by employees and service technicians.

In addition to online catalogs, Besi also uses offline catalogs which are integrated into the HMI applications of Esec products. Another special feature of the machine manufacturer’s catalog creation process is that creators can use various QA functions and easily check file references and hotspots, for example.

Since the integration of the catalog system into Besi's system landscape, the team has already been able to identify numerous improvements. “We have used Quanos SIS.one to automate catalog creation and were able to shorten the search times for users considerably,” says Frank Goller, who is also delighted with the customer service time savings: “As the visual parts search makes identifying spare parts much easier, the number of customer queries has decreased.”

He and his team are very satisfied with the implementation of their digitalization project. And they are not alone: “Our customers and employees enjoy working with the spare parts catalogs and the degree of acceptance was high from the very beginning,” emphasizes Frank Goller.

An important goal of the project was increasing efficiency in aftersales service, and Besi has achieved this goal with Quanos. “Since the introduction of Quanos SIS.one, we have already created and published more than 2,335 catalogs,” summarizes the Director Spares and Tooling, who is looking forward to the upcoming milestones.

“We especially value how easy administration of the system is and the fact that we can use it to display 3D visualizations with ease and without a plug-in, regardless of the browser. Another positive aspect was and still is the excellent collaboration with Quanos. You can tell that the team has a high level of expertise,” he adds.

Based on the positive experiences to date, the catalog system will also be used by other product groups in the future. There are also plans to connect the machine documentation, which will consist of maintenance documents and data from EPLAN.

BE Semiconductor

„At one point we were faced with the task of mapping 150% product catalogs and 100% serial number catalogs, as well as providing an increasing amount of raw data for the spare parts catalogs. Our old system was no longer able to cope with this volume of data.“

Mechanical and plant engineering

You would also like to implement an aftersales project?