Digitize processes

Generate added value through data & increase revenue

Digitalization is more than just a buzzword. It is a strategy. A necessity. A success factor.

But what does reality look like? While production is already largely digitized and automated at many companies in the mechanical and plant engineering sector, there is still a need to catch up in the area of aftersales - and thus potential that needs to be exploited.

Digital aftersales service consists of

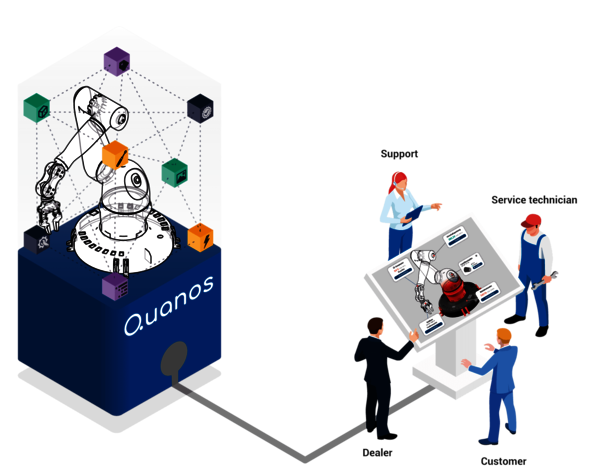

- Centrally stored, linked information

- An extensive networking of machines, plants and systems

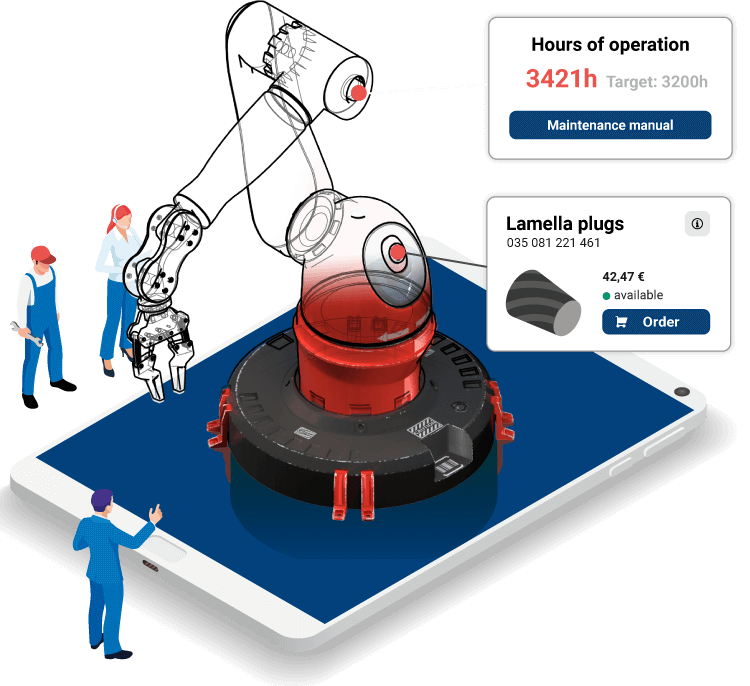

- Intelligent, predictive parts and maintenance management

- Digital processes for handling and ordering

- Parts traceability

- Real-time communication

- Immediate customer support via remote diagnostics and maintenance

Our solution for you:

Quanos SIS.one

Our service information system Quanos SIS.one helps you to implement your digital aftersales strategy and optimize your service processes.

Our software is an all-in-one system that provides you with a 360° service view of your machines and systems. All service-relevant information is digitally stored and intelligently linked in a central system: 2D or 3D spare parts catalogs, parts lists, customer-specific prices, availabilities, technical documentation, circuit diagrams, pneumatic diagrams, repair instructions and much more.

Learn more about Quanos SIS.one

Single source of truth

For all spare parts and service information

Quanos SIS.one gives your aftersales department simple, centralized access to all the information they need to efficiently sell spare and wear parts, generate additional orders, and identify and exploit upsell potential.

Thanks to the shopping cart function and the integration with your ERP system, your customers can order spare parts independently directly in your online catalog - without the support of your service hotline.

In this way, you create the ideal conditions for increasing your revenue in aftersales.

- A digital customer portal with integrated online store for spare and wear parts.

- Machine-specific information, including modifications and maintenance measures that have already been carried out (as maintained)

- Remote services for initial setup, remote maintenance or troubleshooting

- Monitoring of machines and systems

- Options for predictive maintenance