What is a digital 3D spare parts catalog?

A digital spare parts catalog contains the same information as a printed catalog; however, unlike printed information, the digital content never becomes outdated. Digital catalogs also give you the option to display three-dimensional visualizations of spare parts or assemblies, in addition to 2D data.

A 3D catalog allows users to establish more quickly the shape and geometry of components or assemblies through interactions and identify more easily the spare part they need. Read more about the advantages of 3D data in the spare parts catalogue in our expert blog.

3D data is: informative - interaktive - intuitive.

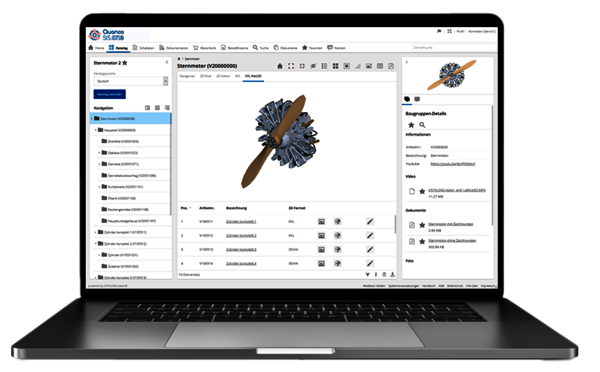

And what does the 3D spare parts catalogue extension look like?

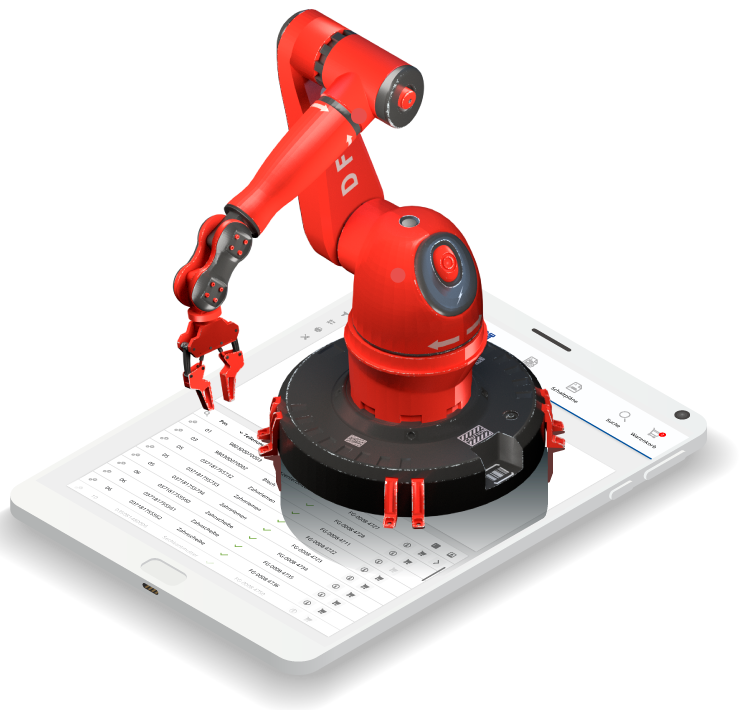

Thanks to 3D data already available, for example from the design department, all spare parts, components and assemblies can be displayed three-dimensionally. The identification and selection of the required parts is thus significantly simplified. Of course, our software and thus also the 3D spare parts catalog extension are designed especially for the needs of your technicians in the field and can be used on mobile devices.

Click on the image to get a direct insight into the software.

- Many companies use 3D data in CAD systems for their design work, but not in other departments. Sales and aftersales departments in particular can benefit from the advantages of 3D visualizations.

- Digital spare parts catalogs with 3D data make it easier for customers and service technicians to identify spare parts, simplifying selection of the correct parts and accelerating the purchasing process.

- With the right catalog software, 3D CAD data can be automated and used in a 3D spare parts catalog without the use of further systems.

„We have used Quanos SIS.one to automate catalog creation and were able to shorten the search times for users considerably,” says Frank Goller, who is also delighted with the customer service time savings: “As the visual parts search makes identifying spare parts much easier, the number of customer queries has decreased.“

BE Semiconductor Industries N.V. Frank Goller, Director Spares and Tooling

3D data is the future of aftersales – and is not nearly used enough

The multi-dimensional views of spare parts are already available at most machinery and plant manufacturers: 90% of them design machinery, vehicles, appliances, or plant using CAD systems.

Yet very few companies make 3D data available to everyone; internal departments or customers usually do not have access to it. This leads to employees within the same company living in two separate worlds.

What is the problem with 2D data?

Error-prone use of 2D data – an example:

A customer calls the Support team. They have a question about a specific part of a machine. The Support employee has difficulty in deciphering which part the customer is referring to using the 2D data available to them.

It would be much easier if the employee had the same perspective of the machine as the customer. 3D data make this possible, even giving you a look inside an assembly.

How does secure 3D visualization in the cloud work?

With our new 3DPartsView module, you can integrate your company's 3D data securely, effectively, and quickly into your spare parts catalogs - all at an unbeatable price-performance ratio. 3DPartsView offers a customized, streamlined package of functions as well as comprehensive security mechanisms to protect your valuable data.

Why are 3D spare parts catalogs indispensable in aftersales?

Company-wide use of 3D data offers a multitude of potential for new business models, sales growth, and digitalizing your aftersales services.

3D spare parts catalogs don’t just bring advantages today. They can also potentially be expanded to form a service information system, which brings together information on parts in machines and plant from various source systems. In this way, 3D data not only makes operation easier, but it is also the key to turning things like predictive maintenance into reality.

How leading machine and plant manufacturers use 3D data

Special machine manufacturer Komptech uses 3D data in its central information and service portal, enabling the company to improve its internal processes in the assembly, production, and service departments.

"CATALOGcreator® is used at Komptech as an information and service portal where we centrally maintain all information about our machines. What was originally intended as a benefit for our customers is now also internally an integral part of our work environment. The software solution is a tool that everybody likes to use. And this constantly improves our processes."

Stefan Gruber-Barowitsch | Head of Technical Documentation

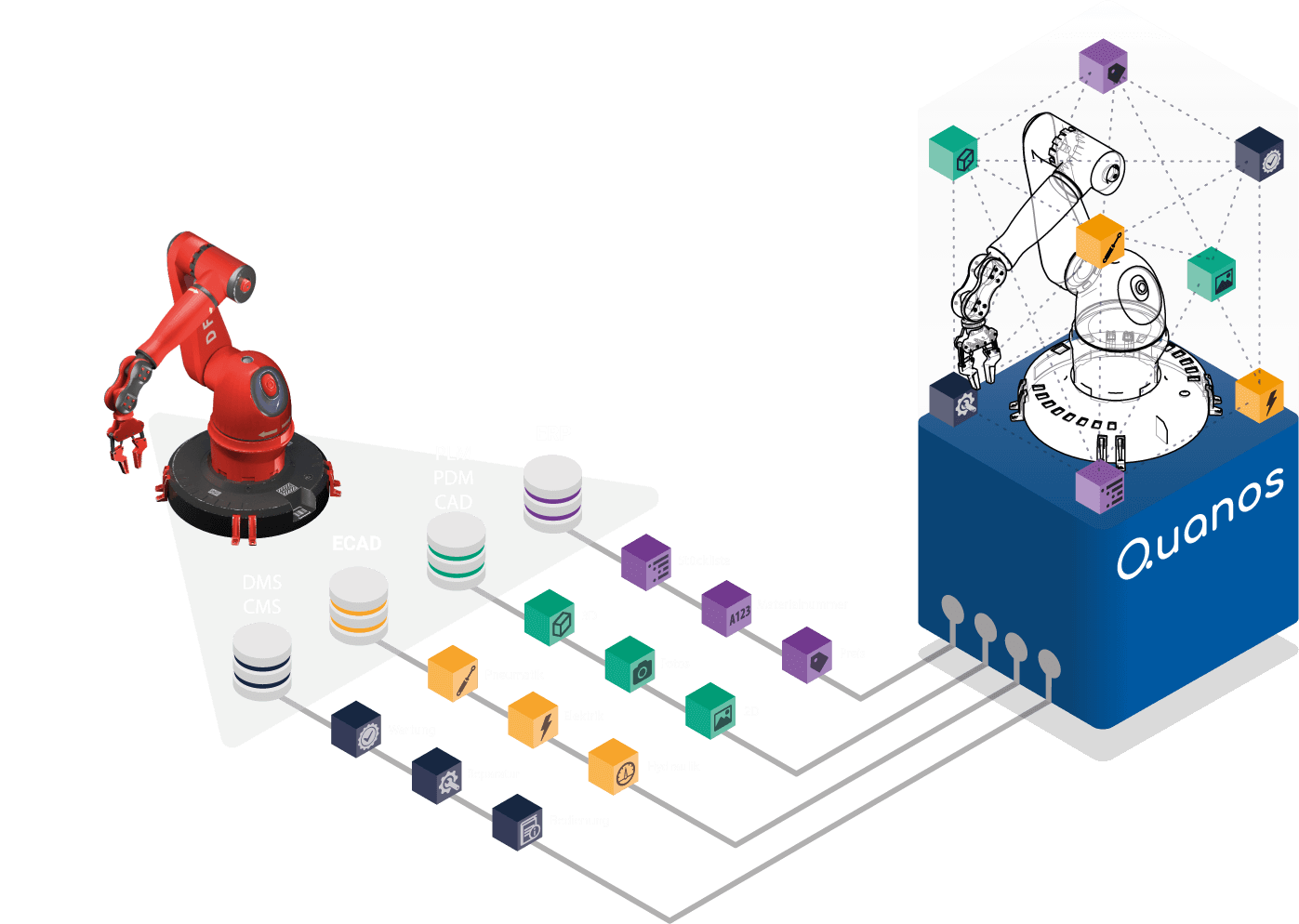

How does 3D data find its way out of the design department and across the company?

3D data from your CAD systems can be used to create a spare parts catalog in an automated or manual manner. It can also easily be used within the technical documentation department. Software solutions from Quanos offer a variety of solutions for this purpose:

-

Convert your 3D data to a lightweight format so that it can be used in other systems without losing relevant information.

-

The integrated display of 3D or 2D graphics created in an automated way appears in Quanos SIS.one, PARTS-PUBLISHER, or CATALOGcreator®. The visualizations can be used interactively regardless of which browser, platform, or device they are viewed on.

-

Individual components in the 3D illustrations are directly linked with the associated data in the parts list and integrated technical documentation.

This means existing 3D data is ultimately also available to other internal departments, without having to buy additional licenses or provide training on your CAD systems. You can decide what level of detail the 3D data in your spare parts catalog or service information system should have.

Are your assemblies, machines or plants large and complex?

If so, you might be interested in the topic of streaming 3D data. Streaming 3D data is a quick and secure way to display even complex 3D models without any time delays. You can find more information in our blog post " Streaming 3D data: Just like Netflix, but for Spare Parts Catalogs”.

Take your 3D data to the next level

Quanos is an industry partner for 3D spare parts catalog projects

We use our expertise to guide you through your 3D data project. We are a long-standing technology partner to suppliers of CAD and 3D software – such as Lattice Technology, KISTERS, Autodesk, Dassault Systèmes, and SolidWorks.

With our partners and our extensive set of tools, we have already delivered numerous successful 3D projects.