Interest aroused?

You would also like to implement an aftersales project?

Thanks to CATALOGcreator®, a software solution for electronic spare parts catalogs, KORSCH, a manufacturer of tablet presses for a global customer network provides customers with optimized search features for replacement, wear and product-related components in a new digital 2D catalog.

KORSCH AG, founded in 1919, develops and manufactures tablet presses and systems for tablet testing and analysis. KORSCH machines produce a large variety of tablets, e.g. pharmaceutical and effervescent tablets, tablets for dishwashers and washing machines, salt, chlorine, fertilizer, alkali, lithium and silver-oxide tablets, and even sugar, herb and mint tablets. The machine manufacturer resides in Berlin and supplies a global customer network.

Since KORSCH had not used electronic catalogs to date, manual design of spare parts catalogs was very time-consuming. Only a Word macro importing data from ERP had supported the process. Modelling the ERP structure, the macro generated parts lists used as the basis of the parts catalog. Corresponding drawings would then be picked out laboriously and assigned to the parts catalog by hand. The resulting PDF templates were used as the basis of the paper catalog. Since the part catalogs were only printed in DIN A4 or DIN A3, original DIN A1 drawings often caused problems. Drawings in the paper catalog were often very small and their details were hardly recognizable. Finally, KORSCH created DVDs containing the PDF files.

Key requirements for KORSCH: get rid of manual expenditure, implement an electronic spare parts catalog with graphical navigation and optimized search features for the customers, and replace all paper catalogs with PDF files. Since the PDF files generated from Word only had limited search options, the main goal was allowing customers to search for required parts in the catalog, and sort them in an easy way. Following a selection contest, KORSCH decided to implement the project with TID Informatik GmbH. CATALOGcreator®, the software solution for electronic spare parts catalogs, met all requirements for a state-of-the-art and user-friendly catalog providing numerous additional benefits, such as the integration of operating and controlling instructions.

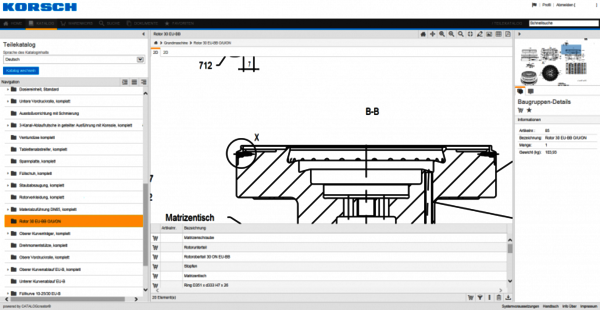

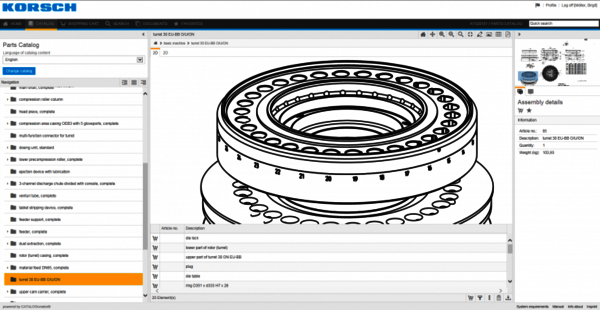

An important feature of the electronic catalog was graphical navigation. Thanks to the hotspots generated by the solution and representing the link between the parts list and the drawing, search queries are very easy. Today, CATALOGcreator® enables KORSCH to provide three types of parts catalogs from one central source. The focus is the classic spare parts catalog. All part attributes from Microsoft Dynamics NAV, KORSCH's ERP system, are transferred to the catalog solution along with additional information on the parts in a semi-automatic procedure.

Almost as a side effect, this generates another catalog type important for KORSCH's customers: the search for product-related components. These components form a component subgroup. A feed shoe, for instance, consists of 50 components, of which only a part relates to the product. The third catalog type is a dedicated wear-parts catalog. Again, the attribute from ERP controls the representation of the part within the catalog. As Ingo Klaer, Head of Development, puts it: "It was fun to see all the options Software CATALOGcreator® has to offer. Thanks to the flexibility of the solution, we have been able to implement a lot of new ideas arising during the project."

Catalog creation today is a semi-automatic process. An automatic process initiated by the PLM solution Teamcenter imports the drawings from the CAD system Siemens NX into the catalog, using CSV interface files. To date, KORSCH uses a 2D catalog with 2D assembly drawings as PDF variant. The offline catalog, including a browser, is available on an USB stick with the company logo and does not require local installation. This allows fast load times of the catalogs and PDF files.

"CATALOGcreator® offers much more than a mere spare parts catalog. We use the solution to retrieve a variety of information from a central location: Operating and controlling instructions, supplier documentation, maintenance and installation instructions as well as information on part attributes, such as the material used, may be located comfortably using the part search. This service portal is a significant added value for users of the catalog and highly praised both internally and externally," says Ingo Klaer. Internally, KORSCH also uses the catalog as a web alternative.

The next project steps have already been scheduled: Instead of the parts catalogs, a collection of assemblies, the plant manufacturer will provide navigation through the entire plant. 2D assembly drawings will be replaced with 3D models that can be zoomed in and rotated on the screen. Even a web shop is on list of future projects. Customers will be able to access their plants at all time and retrieve prices and availability immediately.

"For KORSCH, replacing the paper catalog with a digital solution was a giant leap towards modern service. We use CATALOGcreator® as a container for all kind of information on the parts. We have reached the goals for this project together with TID – and we have even achieved more than we had originally planned. We are looking forward to further fruitful collaboration," the Head of Development at KORSCH summarizes the project.

KORSCH AG

„This service portal is a significant added value for users of the catalog and highly praised both internally and externally.“

Mechanical and plant engineering

You would also like to implement an aftersales project?