Key Info at a Glance

- Service 4.0 marks the future of the service activities of machinery and plant manufacturers and is the basis for competitive business models.

- Networked service data enables manufacturers and producers to get even more out of the sale and operation of machinery and plants.

- Thanks to digitalization, Service 4.0 is now within reach for industrial companies of any size. Getting started is very simple with the right software and experienced partners, and delivers immediate benefits.

What is Service 4.0?

The concept of Service 4.0 is based on Industry 4.0 – just like with the fourth industrial revolution, the focus of “servitization” is the digitalization of the range of services from machinery and plant manufacturers.

Three areas are key here:

- Processes: Workflows in aftersales, sales, and related departments are networked and optimized through Service 4.0.

- Technologies: With big data, the Internet of Things, and digital software tools such as the software solutions from Quanos, manufacturers are able to expand their range of services and offer their customers added value.

- Business models: With optimized processes and the right technologies, machinery manufacturers are laying the foundation for new business models, thereby securing previously untapped turnover potentials.

In order to be ready for the future, organizations should be laying the foundation for the jump to the fourth, fully digitalized service level now. This will enable them to use their resources more efficiently, react more quickly to trends, and inspire their customers throughout the entire product life cycle.

What is a service information system?

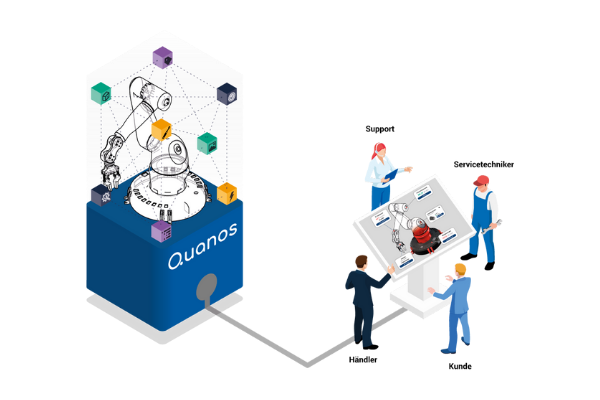

A spare parts catalog system such as Quanos SIS.one increases the efficiency of your service activities. The software brings together parts information and technical documents in one system, giving manufacturers and operators of machinery and plants a central tool to digitalize and optimize their services.

Why is Service 4.0 a Strategic Must in Machinery Construction?

These days, no machinery and plant construction company can afford to let turnover potentials go to waste. The management board must respond to rising costs, economic crises, climate change, and the shortage of skilled workers in order to steer their organization safely into the future.

This will not be achieved through the sale of machinery, devices, and plants alone. To secure cash flow and company growth in a sustainable manner, the digital revolution in the service sector must be completed now.

Benefits of Service 4.0 at a glance

There is immense potential to be exploited in the fourth evolution stage of the service business:

- New sources of revenue and high operating margins

- Differentiation from the competition

- Reinforcing the customer relationship and long-term customer loyalty

- Increased efficiency in aftersales and other departments

- Planning security throughout the entire product life cycle

Advantages for manufacturing companies

It's not only manufacturers who benefit from the advantages of Service 4.0, but also manufacturing companies. Find out how manufacturers can optimize their spare parts storage with Service 4.0 and reduce the risk of machine downtimes.

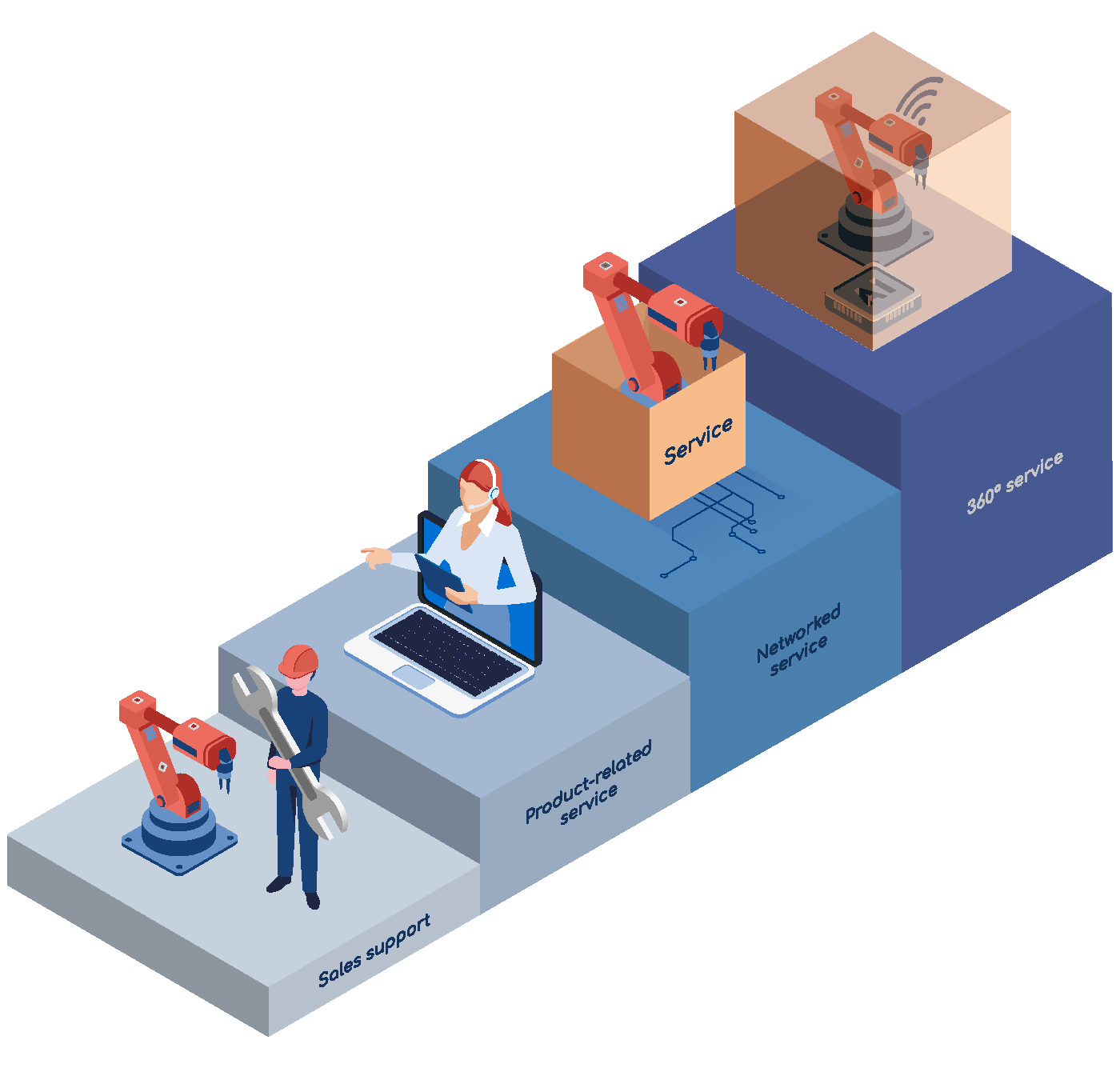

From 0 to Service 4.0: The Service Levels in Machinery Construction

Previously, many machine constructors worked according to the principle “out of sight, out of mind”. With the sale of a product, the sales department had fulfilled its main task and had injected fresh turnover into the company.

But for some time now, the new machines business has no longer been a turnover driver. The service of machinery and plant manufacturers must therefore go through four development stages if they want to remain competitive and solvent.

More and more companies have recognized that spare parts and additional services, such as the maintenance of equipment, offer new turnover potentials. As a result of progressive digitalization, they now have the opportunity to optimize their service and generate new income, based on data. The aim is to offer customers a comprehensive service package throughout the entire life cycle of a product – namely Service 4.0.

What progress has your company made towards Service 4.0?

Use our checklist to find out:

Service 4.0 in Practice: Added Value for Manufacturers and Operators

Do you know what service level your company is at and you now want your service to reach the top level? In order for you to be able to plan concrete actions, below we present some of the key areas of application of the digitalized service business.

The operator model is a megatrend in plant and machinery construction. The product is moving into the background and is giving way to the service. Manufacturers are no longer selling their machinery and plants but rather their output. Customers are saving investment costs and are instead paying regularly for machine performance. The manufacturer takes care of maintenance and operation.

Our Blog series “From CapEx to OpEx” provides you with more information about this.

Supported by digital tools and systems, service technicians and customer service employees can rectify faults in plants without having to put up with long and costly journeys. In Service 4.0, even complex problems can be solved by remote support. Manufacturers therefore become indispensable to their customers.

Read our blog to discover the advantages that remote services offers aftersales.

It is not just industry and service that go through evolution stages but also the maintenance pyramid. The route to the primary goal – financially optimized maintenance – goes via predictive maintenance. This proactive maintenance process is based on the permanent monitoring and evaluation of machinery and process data. This allows future maintenance requirements to be predicted so that maintenance processes can be optimized.

Find out all there is to know about the fundamentals of predictive maintenance and broaden your knowledge using our free white paper on this subject.

B2C customers are used to shopping independently online and being able to make simple changes themselves. More and more B2B providers also rely on online portals with self-service options that reduce the workload of customer service. The digital Service 4.0 self-service portal forms the central interface between the company and customer.

Find out how to use a B2B customer portal successfully.

Companies produce vast quantities of data every day. Using sensors and artificial intelligence, the glut of big data is transformed into a source of valuable information for service technicians and customers who then use this to order the right spare parts at the right time and reduce downtimes. This results in cost savings for manufacturers and plant operators.

Read about how data becomes the driver for intelligent maintenance.

In addition to service portals, text-based dialog systems, also known as chatbots, reduce the workload of aftersales and customer support teams. They can respond to simple requests for spare parts and help customers find information. The prerequisite for digital assistance systems is the same as for all other Service 4.0 applications: a networked database.

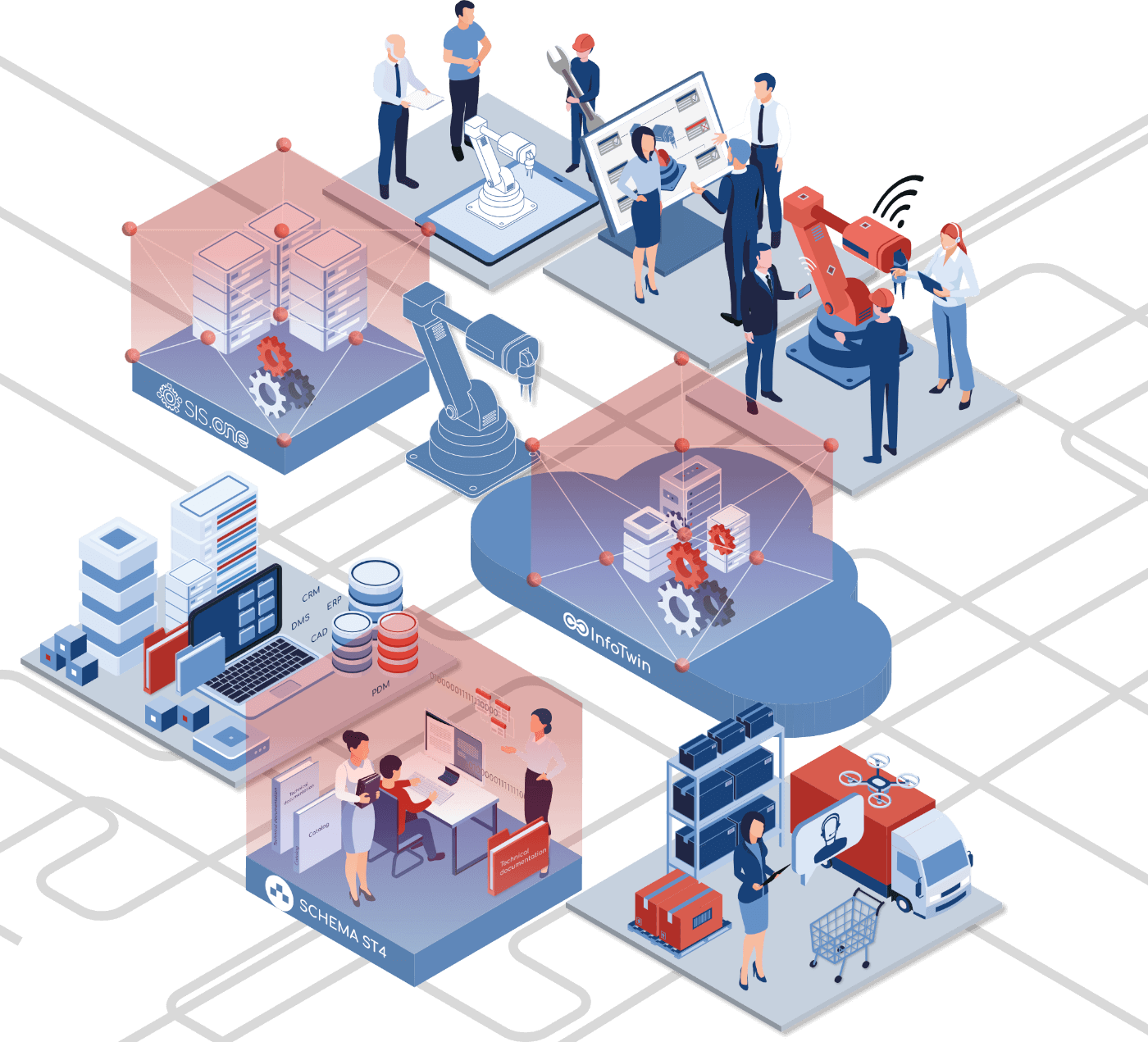

The digital information twin is the epitome of Service 4.0. It forms the central platform for all technical information and service information about a product, machine, or plant. Machine constructors are therefore provided with an intelligent data model of their machinery and plants, which service technicians and customers can use intuitively.

When the right software is used, the DIT forms a future-proof single source of truth that is flexible and upward compatible.

Implementing Service 4.0 – with Our Software Solutions

Regardless of which level of service digitalization your company is on, if you want to reach the top evolution stage, then software tools are a must-have.

We have developed a series of software solutions for this. The quickest way to get started is with a digital spare parts catalog. It's quick and easy to create using our Quanos SIS.one spare parts catalog system and can be published across different media. Quanos SIS.one ensures that processes and data are transported from the analog world into the digital world and can be gradually expanded to form an all-in-one service information system.

Do you want to create the basis for new business models? Then the Quanos InfoTwin is the right platform for you. The new, modular cloud solution easily and intelligently networks information from technical documentation, spare parts management, and other sources. Quanos InfoTwin consolidates disparate information to form a digital information twin, creating the basis for new business models and smart services.

Take Your Service to the Next Level

With our experience in plant and machinery construction, and our intuitive software solutions, we will guide you through your service transformation. The security of your data and your individual goals are at the top of our list. We look forward to hearing from you: